In the palm oil processing industry, energy efficiency has become a crucial factor for businesses aiming to reduce operational costs and enhance competitiveness. The goal of achieving a steam consumption of less than 300 kg/t oil is not only an environmental imperative but also a significant economic advantage. This article delves into the energy-saving design of palm oil equipment by Penguin Group, exploring the core technologies and mechanisms that enable such low steam consumption.

Energy consumption in palm oil processing, especially steam consumption, accounts for a large proportion of the total operational costs. By reducing steam consumption to below 300 kg/t oil, companies can significantly cut down on energy expenses. For instance, a medium - sized palm oil processing plant with an annual output of 10,000 tons of oil could save up to hundreds of thousands of dollars in energy costs if it achieves this steam - saving target. Moreover, it aligns with global environmental trends, reducing the carbon footprint of the palm oil industry.

The thermal energy recovery system is a key component in reducing steam consumption. Penguin Group's equipment is equipped with a highly efficient heat exchanger that can recover waste heat from the production process. For example, the heat from the hot oil after the pressing process can be transferred to the incoming cold water or raw materials. This not only pre - heats the materials but also reduces the amount of steam needed for further heating. Studies have shown that this heat recovery system can reduce steam consumption by up to 20%.

The heating unit in Penguin Group's palm oil equipment is designed with advanced heating elements and insulation materials. The heating elements have a high heat transfer coefficient, which can quickly and evenly heat the materials. The insulation materials prevent heat loss, ensuring that most of the heat generated is used for the processing of palm oil. As a result, less steam is required to maintain the required processing temperature.

Process optimization is another important aspect. By adjusting the processing parameters such as the pressing time, temperature, and pressure, the overall energy efficiency can be improved. For example, optimizing the pressing process can reduce the amount of residual oil in the palm cake, which in turn reduces the need for additional heating and steam for further extraction.

High - quality motors are essential for the stable operation of palm oil equipment. Penguin Group uses energy - efficient motors with high power factors. These motors consume less electricity while providing sufficient power for the equipment. For example, compared with ordinary motors, the energy - efficient motors used in their equipment can reduce electricity consumption by about 15%.

The pressure vessels in the palm oil equipment are made of high - quality materials and manufactured with advanced processes. They can withstand high pressure and temperature, ensuring the safety and stability of the processing. According to industry standards, the service life of these pressure vessels can reach more than 15 years, which reduces the need for frequent replacement and maintenance, thus saving costs in the long run.

High - quality pumps are used to transfer various fluids in the palm oil processing. These pumps have high efficiency and low energy consumption. They can accurately control the flow rate and pressure, ensuring the smooth progress of the production process. For example, the pumps used in Penguin Group's equipment can reduce the energy consumption of the fluid transfer process by about 10%.

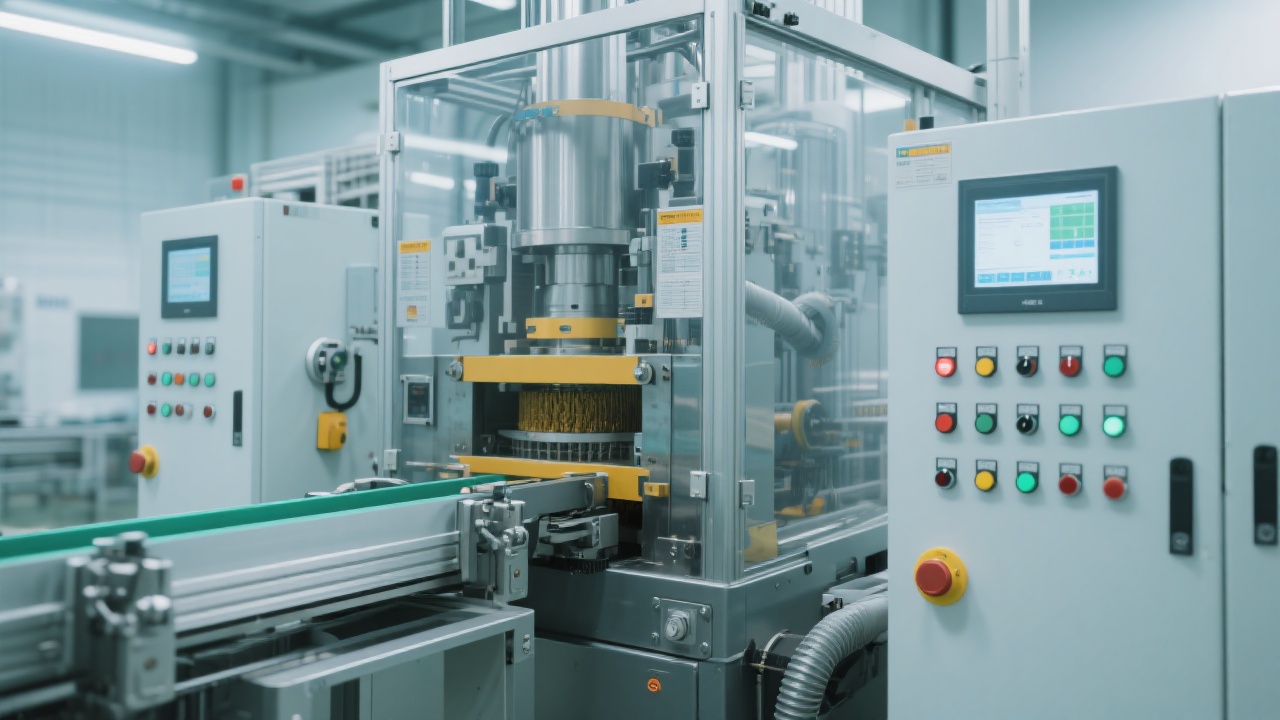

The PLC intelligent control system in Penguin Group's palm oil equipment enables fully automatic operation and ensures reliable 24 - hour high - load operation. The system can monitor and adjust various parameters in real - time, such as temperature, pressure, and flow rate. For example, if the temperature in the heating unit is too high, the system will automatically reduce the steam supply. This not only improves the energy efficiency but also reduces the risk of equipment failure. In a real - world case, a palm oil plant using this PLC control system has achieved a continuous production uptime of over 95%.

Penguin Group's palm oil equipment has passed the national first - and second - class pressure vessel standards and ISO9001:2000 certification. These certifications are a guarantee of the equipment's safety, quality, and performance. For example, the compliance with pressure vessel standards ensures that the equipment can operate safely under high - pressure conditions, reducing the potential safety hazards. The ISO9001:2000 certification indicates that the equipment is produced under a strict quality management system, ensuring its long - term reliability.

The energy - saving design of Penguin Group's palm oil equipment has a significant impact on customer operations. By reducing steam consumption and electricity consumption, customers can lower their operational costs. At the same time, the high - load stability and long - term reliability of the equipment can increase the production capacity and product quality. For example, a customer in Nigeria reported a 25% reduction in energy costs and a 15% increase in production capacity after using Penguin Group's equipment.

You may wonder, have you ever paid attention to the continuous operation stability of your palm oil equipment? If you want to learn more about how Penguin Group's palm oil equipment can help you achieve energy - saving goals and improve production efficiency, click here. Choosing Penguin Group is not just about buying a piece of equipment; it's an investment in a sustainable and profitable production solution.