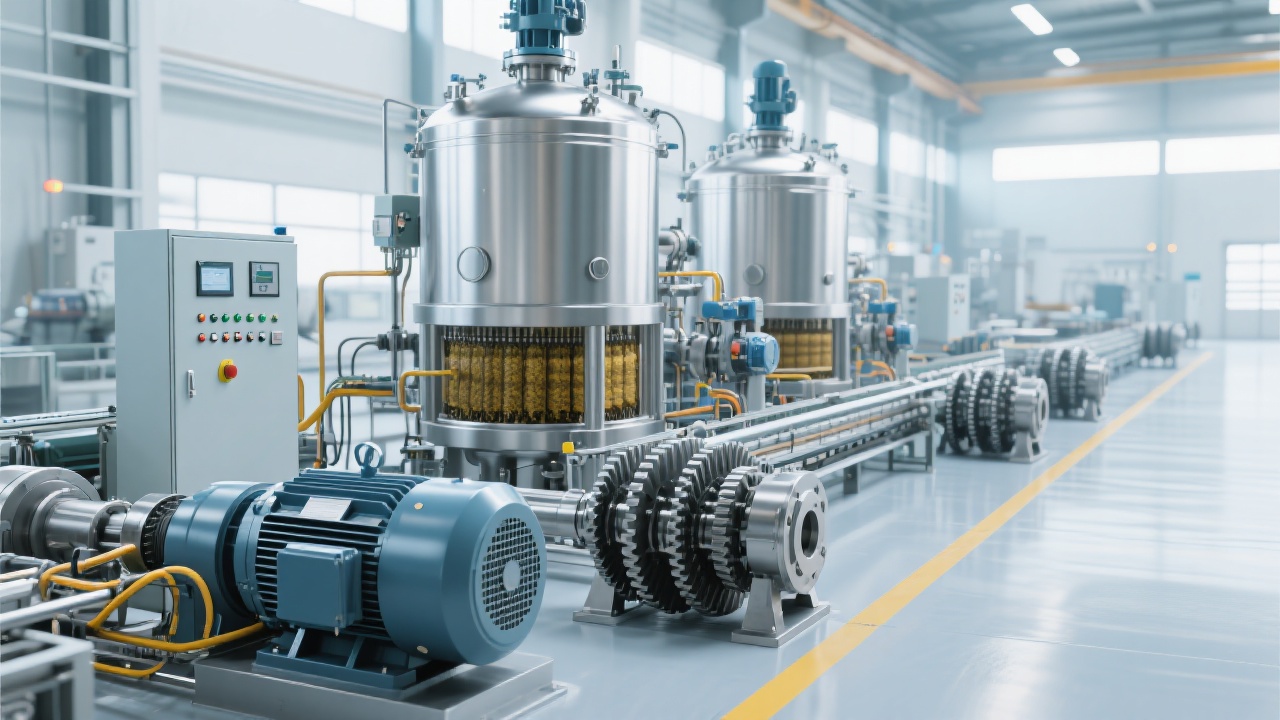

In the competitive landscape of palm oil manufacturing, integrating Programmable Logic Controller (PLC) systems has emerged as a transformative step toward efficiency and consistency. By automating key stages—feeding, pressing, and oil-water separation—EC-level PLC solutions significantly reduce manual labor and optimize operational parameters in real-time. This article explores how the strategic deployment of industrial sensors and advanced control logic enhances palm oil production lines, driving tangible gains such as reduced energy consumption and higher throughput, with a keen focus on applicability for small- and medium-sized enterprises (SMEs).

At the heart of the automation lies the carefully designed PLC logic control strategy that governs the entire palm fruit processing workflow. The PLC continuously monitors and adjusts parameters such as feed rate, pressing pressure, and temperature to maintain optimal process conditions. This precise control has proven to deliver enhanced production consistency, mitigating fluctuations caused by raw material variability or human factors. For example, implementation of PID (Proportional-Integral-Derivative) control loops enables dynamic regulation of pressing force to maximize oil yield while preventing equipment stress.

Such tight automation control translates to a measurable reduction in defects and downtime, delivering on the promise of smoother operations and predictable output quality. Enterprises adopting this approach have reported an average increase in unit production efficiency of 15%–20% within the first six months of PLC integration.

Critical to the PLC’s effectiveness is the deployment of industrial-grade sensors at key process nodes. Pressure sensors installed on the pressing chamber provide real-time feedback essential for maintaining appropriate extraction force. Temperature sensors embedded in the hot water system ensure the heating parameters remain within the ideal range to facilitate efficient oil separation. Additionally, flow meters monitor the volumetric rates of both palm fruit slurry and separated liquids, providing the PLC with data to coordinate timing and valve adjustments.

These sensors feed a rich dataset into the PLC’s control logic, enabling the system not only to execute tasks but also to anticipate operational anomalies. For instance, a subtle rise in pressure deviation beyond set thresholds triggers an immediate fault alert, permitting preventive intervention before a full-scale shutdown occurs.

A pivotal benefit derived from the automated system is the significant reduction in energy and steam consumption, substantiated by collected operational data. Automated control stabilizes steam usage to below 300 kg per ton of processed palm oil, a marked improvement over conventional systems that often experience erratic steam input due to manual regulation.

Electric power consumption also sees a decline, with recent implementations averaging under 22 kWh per ton of oil produced. These efficiency gains are attributable to optimized motor speeds, smarter valve actuation, and minimized idle running time—all orchestrated via the PLC’s sequencing and data monitoring capabilities.

| Metric | Before Automation | After PLC Implementation | Improvement |

|---|---|---|---|

| Steam Consumption (kg/ton oil) | ~450 | <300 | ~33% Reduction |

| Electric Power Consumption (kWh/ton oil) | ~30 | ≤22 | ~27% Reduction |

| Production Efficiency Increase | Baseline | 15%–20% | Significant Gain |

SMEs aiming to reap these automation benefits should adopt a phased approach to equipment upgrades. Initial steps involve assessing current system compatibility, including mechanical interfaces and communication protocols. Modern PLCs with modular I/O architecture facilitate integration even in legacy lines.

Moreover, workforce readiness is crucial; effective operator training programs focused on PLC interface operation, troubleshooting, and preventive maintenance are recommended. Providing operators with hands-on experience in configuring alarms and interpreting sensor data fortifies the system’s overall resilience.

The deployment of PLC-driven predictive maintenance protocols represents a paradigm shift from reactive repairs to scheduled upkeep. By continuously analyzing sensor trends and fault logs, the system can forecast potential failures and recommend maintenance before breakdowns occur.

This approach has demonstrated reductions in unplanned downtime by up to 40%, directly correlating to increased overall equipment effectiveness (OEE). Such gains are vital in maximizing throughput continuity, thereby safeguarding business profitability.

“As the global palm oil market demands higher yields and energy efficiencies, embracing intelligent automation systems becomes not just an option but a necessity.” — Industry Trend Insight

Discover how Penguin Palm Oil Pressing Lines equipped with cutting-edge PLC systems can empower your enterprise with remote diagnostics and smart maintenance. Streamline your production, reduce energy costs, and elevate operational reliability—all within one integrated solution designed for forward-thinking palm oil manufacturers.