In the competitive palm oil industry, especially in tropical regions like Nigeria, consistent output quality and energy efficiency are no longer optional—they’re critical for survival. Manual operations often lead to inconsistent temperature control during pressing, unstable oil-water separation, and unnecessary waste. That’s where PLC-based automation makes a measurable difference.

Traditional palm oil processing relies heavily on operator judgment—adjusting steam valves, monitoring press temperatures, or manually setting centrifuge speeds. But even experienced technicians can’t maintain precise parameters over long shifts. This results in up to 5–8% variation in extraction rates and frequent product rework.

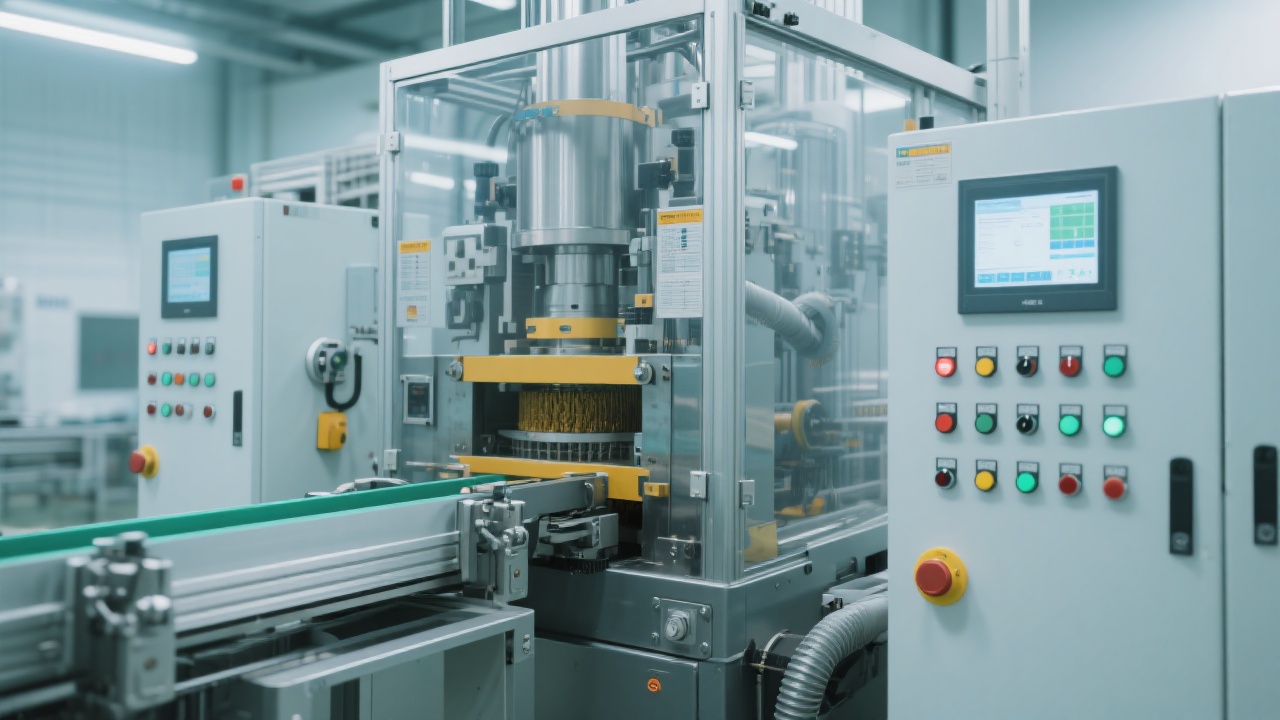

Penguin Group’s custom-built PLC system uses real-time sensor feedback to regulate key process points:

| Process Stage | Manual Operation | Automated (PLC-Controlled) |

|---|---|---|

| Steam Consumption | ~350 kg/t oil | <300 kg/t oil |

| Electricity Use | ~28 kWh/t oil | <22 kWh/t oil |

| Daily Yield Variability | ±7% | ±2% |

For processors in high-humidity environments such as West Africa, maintaining stable production isn’t just about uptime—it’s about reducing maintenance costs, minimizing raw material loss, and ensuring compliance with international standards (like ISO 22000).

One Nigerian mill reported a 12% increase in daily throughput after implementing Penguin Group’s automated solution. Their team also saw a 40% drop in unplanned downtime due to fewer manual errors in critical steps like degumming and bleaching.

The secret? Smart sensors that monitor viscosity, moisture content, and pH levels—not just in the reactor, but across the entire line. These inputs feed into a logic engine that adjusts valve positions, pump speeds, and heating cycles automatically.

If you're still relying on human operators to manage your press temperature curves or oil-water separation, you may be losing more than you realize—both in yield and reputation.

Penguin Group’s tailored automation packages aren’t one-size-fits-all. We work with your team to map existing workflows, identify bottlenecks, and deploy only what’s needed for your specific plant size and output goals.

Ready to reduce variability, cut energy use, and boost consistency?

Get Your Free Process Audit Today