This article focuses on the daily maintenance essentials of the Penguin palm oil pressing production line. It systematically explains the maintenance cycles, lubrication, and cleaning methods of core components such as gears, bearings, and pump sets. Preventive maintenance is emphasized as crucial for extending equipment lifespan and boosting production efficiency.

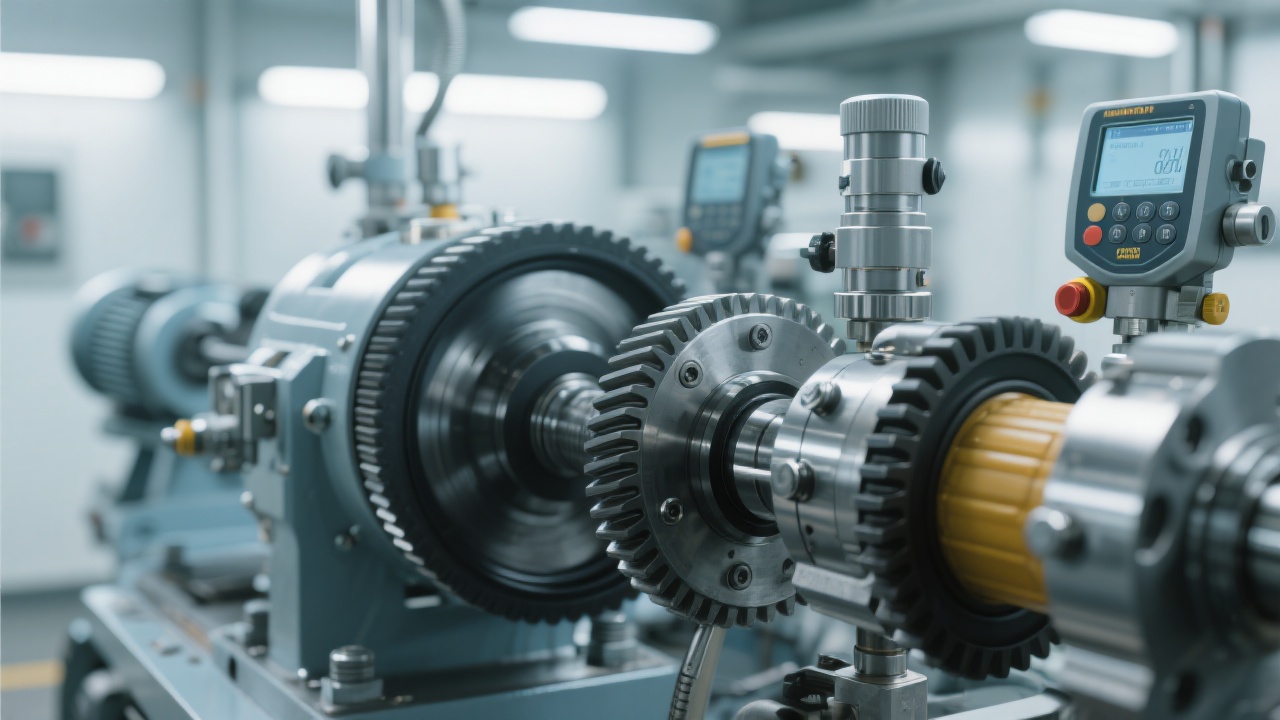

Gears, as the key power - transmission parts in the production line, should be lubricated every 200 operating hours. Regularly check for wear and tear, and replace them if the tooth surface wear exceeds 10%. Bearings need to be cleaned and greased every 150 hours. Improper lubrication can cause bearing overheating, which may lead to a 30% reduction in equipment efficiency.

Pump sets are responsible for transporting palm oil and other liquids. They should be inspected for leaks and pressure stability every 100 hours. Any abnormal noise or vibration during operation indicates potential problems that need immediate attention.

Adopting a preventive maintenance strategy can reduce unexpected breakdowns by up to 40%. This involves creating a detailed maintenance schedule that includes regular equipment inspections, part replacements, and system calibrations. By following this schedule, operators can detect and address potential issues before they escalate into major problems.

Common faults in the palm oil production line include motor malfunctions, pipeline blockages, and sensor failures. For motor malfunctions, check the power supply, fuse, and motor windings. In case of pipeline blockages, use high - pressure flushing or mechanical dredging methods. Sensor failures can be resolved by recalibrating or replacing the sensors.

The emergency handling process should be designed to minimize downtime. For example, having a standby pump set can reduce the production halt time from several hours to just 30 minutes in case of a pump failure.

Water quality management is essential for the proper operation of the production line. Poor water quality can cause corrosion of pipes and equipment, reducing their lifespan by up to 20%. Regularly test the water quality and use water treatment agents if necessary.

Seal replacement is also a critical maintenance task. Replace seals every 300 hours to prevent oil leakage, which can not only waste resources but also pose safety hazards.

Electrical safety inspections should be carried out monthly. Check the insulation of wires, the operation of electrical switches, and the grounding system to ensure the safety of the production line.

The Penguin palm oil pressing production line comes with core component warranties. Our professional maintenance support team is ready to provide you with 24/7 technical assistance. Whether you are a production line operator or a maintenance engineer, we can help you keep your equipment in top - notch condition.

Contact us now to get professional technical support for your palm oil production line!