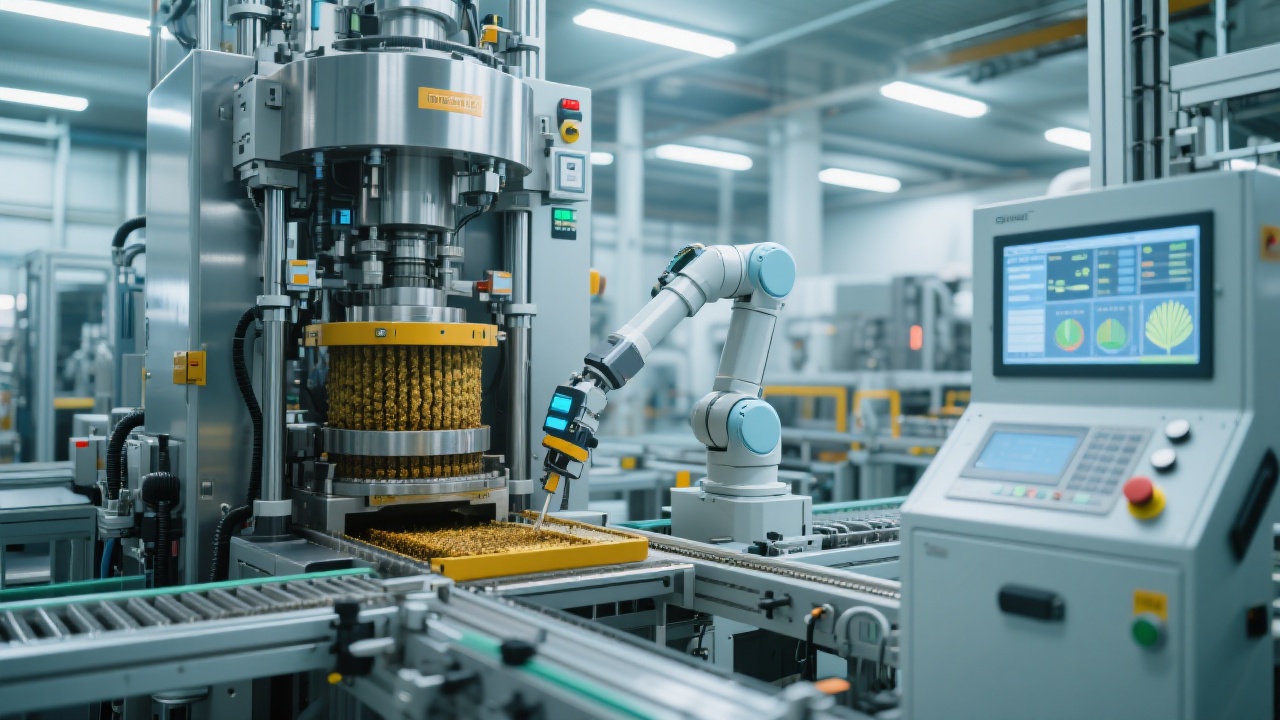

The palm oil processing industry in Nigeria has witnessed significant growth in recent years, driven by the increasing demand for palm oil both domestically and internationally. With the expansion of the industry, there is a pressing need for high - performance and energy - efficient palm oil processing equipment. Penguin Group recognized this market demand and designed a series of advanced palm oil processing equipment specifically tailored for the Nigerian market.

One of the most remarkable features of these palm oil processing equipment is their excellent energy - saving performance. The steam consumption of the equipment is lower than 300kg/t oil, and the power consumption is less than 22kWh/t oil. These low energy consumption figures are achieved through a combination of advanced technologies. For example, the equipment adopts energy - efficient heating systems and intelligent control algorithms that can adjust the energy input according to the actual processing requirements.

| Energy Indicator | Standard Value |

|---|---|

| Steam Consumption | Less than 300kg/t oil |

| Power Consumption | Less than 22kWh/t oil |

The high - quality materials and advanced manufacturing processes of key components such as high - efficiency motors, pressure vessels, and pumps play a crucial role in ensuring the stability and durability of the equipment. The motors are made of high - grade magnetic materials, which not only improve the efficiency but also reduce the heat generation during long - term operation. Pressure vessels are manufactured with high - strength steel that meets strict quality standards, providing reliable containment for high - pressure processes. Pumps are designed with precision machining techniques to ensure smooth fluid transfer.

The PLC intelligent control system is the core of the palm oil processing equipment. It can monitor and adjust the operation of the entire equipment in real - time, ensuring 24 - hour continuous high - load operation. For instance, it can automatically detect the temperature, pressure, and flow rate of various processing stages and make timely adjustments to maintain optimal operating conditions. This not only improves the processing efficiency but also reduces the risk of equipment failure.

The equipment complies with national pressure vessel standards and the ISO9001:2000 quality management system. Compliance with pressure vessel standards ensures the safety of the equipment during high - pressure operation. The ISO9001:2000 quality management system guarantees the consistency and reliability of the product quality, providing a solid foundation for long - term operation and investment.

In practical applications, the equipment has obvious maintenance advantages. The modular design of the equipment allows for easy replacement of components, reducing the maintenance time and cost. Moreover, the long - term energy - saving effect can significantly reduce the operating cost. For example, a palm oil processing plant using this equipment can save up to 20% of energy costs annually compared to traditional equipment.

Q: How does the PLC intelligent control system improve the efficiency of the equipment?

A: The PLC intelligent control system can monitor and adjust the key parameters of the equipment in real - time, such as temperature, pressure, and flow rate. By maintaining optimal operating conditions, it can improve the processing speed and reduce the processing time, thus enhancing the overall efficiency.

Q: What are the benefits of the equipment complying with national pressure vessel standards and ISO9001:2000 quality management system?

A: Compliance with pressure vessel standards ensures the safety of the equipment during high - pressure operation, reducing the risk of accidents. The ISO9001:2000 quality management system guarantees the consistent quality of the equipment, providing a reliable guarantee for long - term use and investment.

If you are interested in learning more about our high - performance, energy - efficient palm oil processing equipment and how it can transform your business, click here to explore further.