Nigeria's palm oil industry is experiencing significant growth, presenting both opportunities and challenges for equipment suppliers. This article aims to provide a comprehensive analysis of the market demand and key equipment selection criteria in the Nigerian palm oil sector, guiding procurement decision - makers and technical managers in making rational investments and technological upgrades.

To accurately understand the market needs, it is essential to consider local raw material characteristics, production scales, and environmental factors. For example, Nigerian palm fruits may have unique physical and chemical properties compared to those in other regions. Approximately 80% of palm oil production in Nigeria is carried out by small - to - medium - sized enterprises, with production scales varying from 10 - 50 tons per day. These enterprises often face challenges such as limited capital, lack of advanced technology, and unstable power supply.

Multifunctional and automated palm oil processing equipment plays a crucial role in enhancing production efficiency and product quality. For instance, an automated control system can precisely control the temperature, pressure, and time during the processing, reducing human errors and ensuring consistent product quality. A case study shows that a palm oil processing plant in Nigeria increased its production efficiency by 30% after upgrading to a fully automated system.

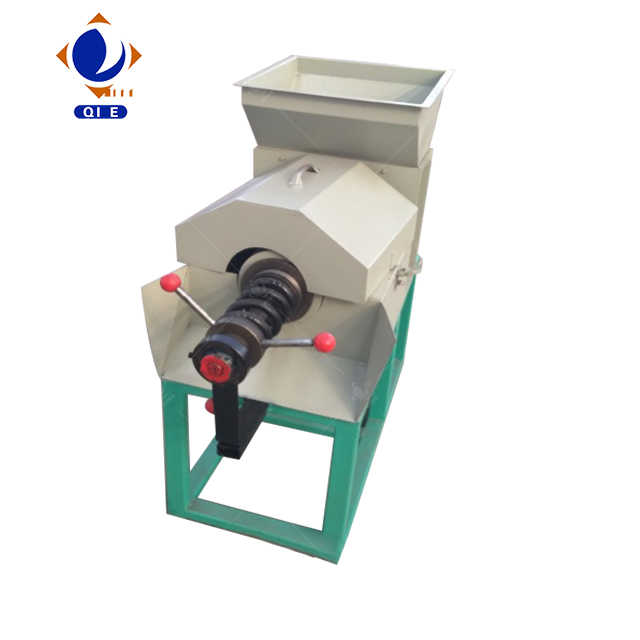

The palm oil processing technology chain includes crushing, separation, pressing, and refining. Each step is vital for the final product quality. The crushing process should break the palm fruits effectively, with a recommended crushing rate of over 95%. The separation process can separate the pulp from the shell, and the pressing process extracts the oil from the pulp. In the refining process, impurities are removed to meet the international quality standards. The following table shows the key parameters of each process:

| Process | Key Parameter |

|---|---|

| Crushing | Crushing rate > 95% |

| Separation | Separation efficiency > 90% |

| Pressing | Oil extraction rate > 80% |

| Refining | Impurity removal rate > 98% |

Equipment design should comply with national pressure vessel standards and ISO 9001:2000 quality systems. This not only ensures the safety of production but also enhances the reliability and durability of the equipment. For example, pressure vessels used in the palm oil processing must meet strict safety requirements to prevent accidents such as explosions and leaks. Equipment that meets these standards can reduce maintenance costs by up to 20% over a five - year period.

Penguin Group offers a full - range of services from design, installation to professional technical maintenance. This comprehensive service system can significantly reduce operational risks. For example, in case of equipment breakdowns, the technical support team can provide on - site maintenance within 48 hours in most cases, minimizing production downtime.

We encourage readers to ask questions and share their concerns. Our experts will answer your questions and provide further guidance. Leave your questions in the comment section below!

If you are looking to upgrade your palm oil production technology in Nigeria, Penguin Group's high - efficiency equipment and comprehensive services can help you achieve technological upgrades and business growth. Click here to learn more!