In today's competitive landscape of the palm oil industry, the automation of production lines has become a crucial factor for small and medium-sized oil enterprises to enhance efficiency, reduce costs, and ensure sustainable development. This article delves into the pivotal role of industrial sensors in the automation control system of Penguin palm oil pressing production lines, offering in-depth insights for industry decision-makers and technical managers.

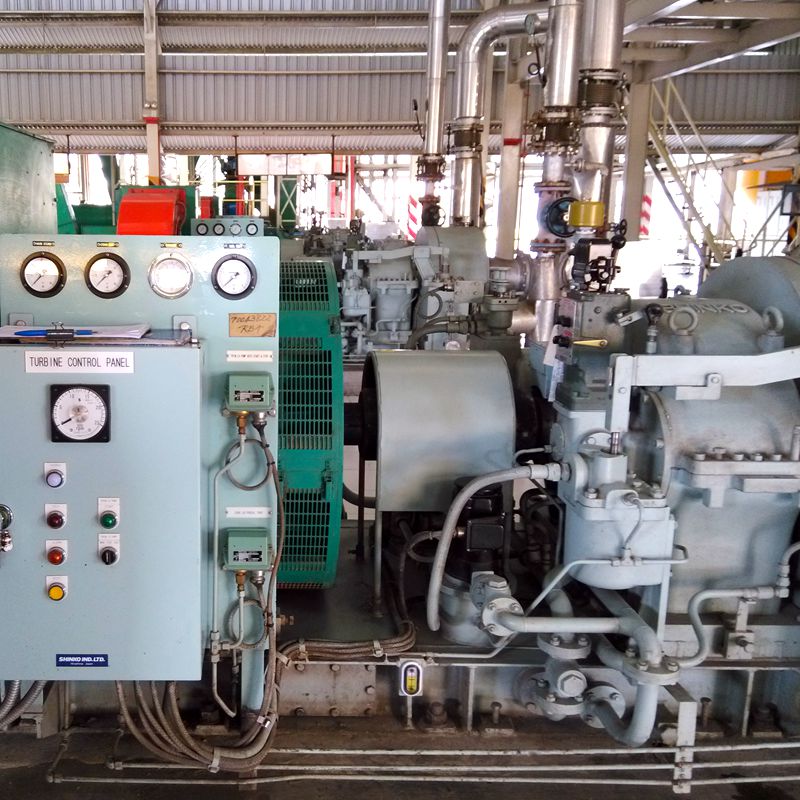

The Penguin palm oil pressing production line is equipped with a sophisticated PLC automation system. In the key processes of feeding, pressing, and oil-water separation, the PLC system plays a significant role in logical control and optimization. For instance, during the feeding process, the PLC system can precisely control the feed rate based on the production capacity requirements. By adjusting the speed of the conveyor belt, it ensures a stable and continuous supply of palm fruits to the press, which can increase the production efficiency by approximately 15% compared to traditional manual feeding methods (as shown in Figure 1).

In the pressing process, the PLC system can optimize the pressing pressure according to the characteristics of palm fruits. Through real - time adjustment, it can extract more palm oil while reducing the energy consumption. Data shows that with the optimized PLC control, the energy consumption per ton of palm fruits can be reduced by about 12%.

Industrial sensors, including pressure, temperature, and flow sensors, are the core components of the automation control system. These sensors are strategically deployed at various positions in the production line to collect real - time data on production parameters. Pressure sensors are installed at the inlet and outlet of the press to monitor the pressure changes during the pressing process. If the pressure exceeds the normal range, it may indicate a blockage or mechanical failure in the press. Temperature sensors are placed in key areas such as the press chamber and the oil - water separation tank. Abnormal temperature rises can be early signs of equipment overheating or friction, which can lead to serious damage if not addressed in time. Flow sensors are used to measure the flow rate of palm fruits, oil, and water in the production line, ensuring a balanced and efficient production process (as shown in Figure 2).

The data collected by these sensors is transmitted to the control center in real - time. Combined with the logical control of the PLC system, it can achieve fault early - warning and remote monitoring. For example, when the temperature sensor detects an abnormal increase in temperature, the system can send an alarm signal to the maintenance personnel's mobile devices, allowing them to take preventive measures in advance. This preventive maintenance approach can reduce the equipment downtime by up to 20%, significantly improving the overall stability of the production line.

Let's take a look at some real - world case studies. A medium - sized palm oil enterprise implemented the Penguin palm oil pressing production line automation system. After the implementation, the production capacity increased by 25% within six months. The energy consumption per unit of production decreased by 18%, which led to a significant cost reduction. Moreover, the quality of the palm oil produced was more stable, with a higher oil yield and better purity.

Another case is a small - scale oil enterprise. By upgrading to the automated system, it was able to improve the utilization rate of raw materials. The oil extraction rate increased from 90% to 93%, which directly translated into higher profits. These case studies clearly demonstrate the effectiveness of automation in improving productivity and reducing costs.

For small and medium - sized oil enterprises looking to upgrade their equipment, several factors need to be considered. In terms of system integration, it is essential to ensure that the new automation system can be seamlessly integrated with the existing production equipment. Compatibility issues can lead to inefficiencies and even system failures. For example, when selecting sensors, they should be compatible with the PLC system in terms of communication protocols and data formats.

Personnel training is also a crucial aspect. The enterprise needs to train its employees to operate and maintain the new automation system. A well - trained workforce can ensure the proper functioning of the system and timely troubleshooting. It is recommended that enterprises allocate at least 10% of the total project cost for personnel training.

The Penguin palm oil pressing production line offers a comprehensive solution for small and medium - sized oil enterprises. With its advanced PLC automation system and industrial sensor applications, it can significantly improve the production efficiency, reduce energy consumption, and ensure the stability of the production process. The system is designed to be highly compatible with existing equipment, making it easy for enterprises to upgrade.

If you are a decision - maker or technical manager in the palm oil industry, and you are looking for a reliable and efficient solution to upgrade your production line, the Penguin palm oil pressing production line is the ideal choice. Contact us now to learn more about our products and services, and let us help you achieve sustainable development in the palm oil industry. Click here to get in touch with our experts.