As Nigeria's palm oil industry surges forward, your equipment choices profoundly influence operational success. Selecting palm oil processing machinery tuned to local raw material characteristics and production scales isn’t merely a purchase—it’s a long-term investment in efficiency, safety, and profitability. This guide walks you through essential factors to consider, ensuring each Nigerian palm oil enterprise can confidently navigate from raw fruit to refined oil with automated precision.

The unique attributes of Nigerian palm fruit — including oil content variability (averaging 20-25%), moisture levels around 45%, and fibrous composition — demand equipment that adapts for optimal extraction. Moreover, unpredictable seasonal harvests and agro-climatic changes necessitate machinery capable of flexible throughput, accommodating batch sizes from smallholder setups (1-5 tons/day) to mid-sized processors (up to 20 tons/day).

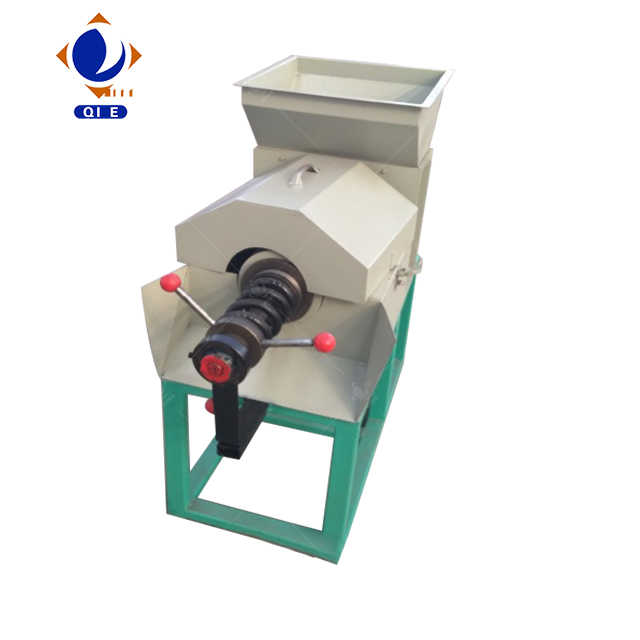

Your chosen equipment must harmonize multi-stage processing (from crushing to refining) with automation that reduces manual intervention. Automated control systems decrease error margins and labor costs, boosting output consistency and quality. For instance, integrated PLC systems can monitor throughput, temperature, and pressure in real-time, ensuring compliance with process parameters and minimal downtime.

Case in point: A mid-sized Nigerian processor adopting advanced semi-automatic screw presses reported a 15% uplift in oil yield and a 20% reduction in processing time within six months—demonstrating automation’s direct impact on profitability.

The palm oil processing chain typically encompasses:

Each stage features optimized technology designed to reduce energy consumption—such as steam use capped below 300kg per ton of oil and electrical demand below 22kWh per ton—underscoring sustainable processing.

Compliance with Nigeria’s national classifications for pressure vessels, alongside ISO 9001:2000 quality management systems, is non-negotiable. Equipment certified under these standards assures you of mechanical integrity and operational safety during continuous 24-hour production cycles. This commitment drastically lowers downtime risks and regulatory challenges.

Your equipment is not just machinery—it is a reliability cornerstone. Penguin Group’s machines are engineered to meet the highest safety benchmarks, combining robust steel fabrication with real-time pressure monitoring systems.

Beyond hardware, Penguin Group partners with you throughout the lifecycle—from conceptual design and turnkey installation to fine-tuning and periodic maintenance. This holistic approach:

| Key Parameter | Typical Value | Benchmark Impact |

|---|---|---|

| Steam Consumption | < 300 kg/ton oil | Lower energy cost, reduced greenhouse gas emissions |

| Electricity Usage | < 22 kWh/ton oil | Cost savings with efficient motor drives |

| Operational Uptime | > 95% in 24/7 operation | Maximized throughput and ROI stability |

Are you currently seeking palm oil equipment that delivers cost-efficiency, reliability, and full automation tailored to Nigeria's unique market? Choosing Penguin Group’s palm oil processing solutions means acquiring not just a machine, but a production partner committed to turning your investment into sustainable, measurable returns.