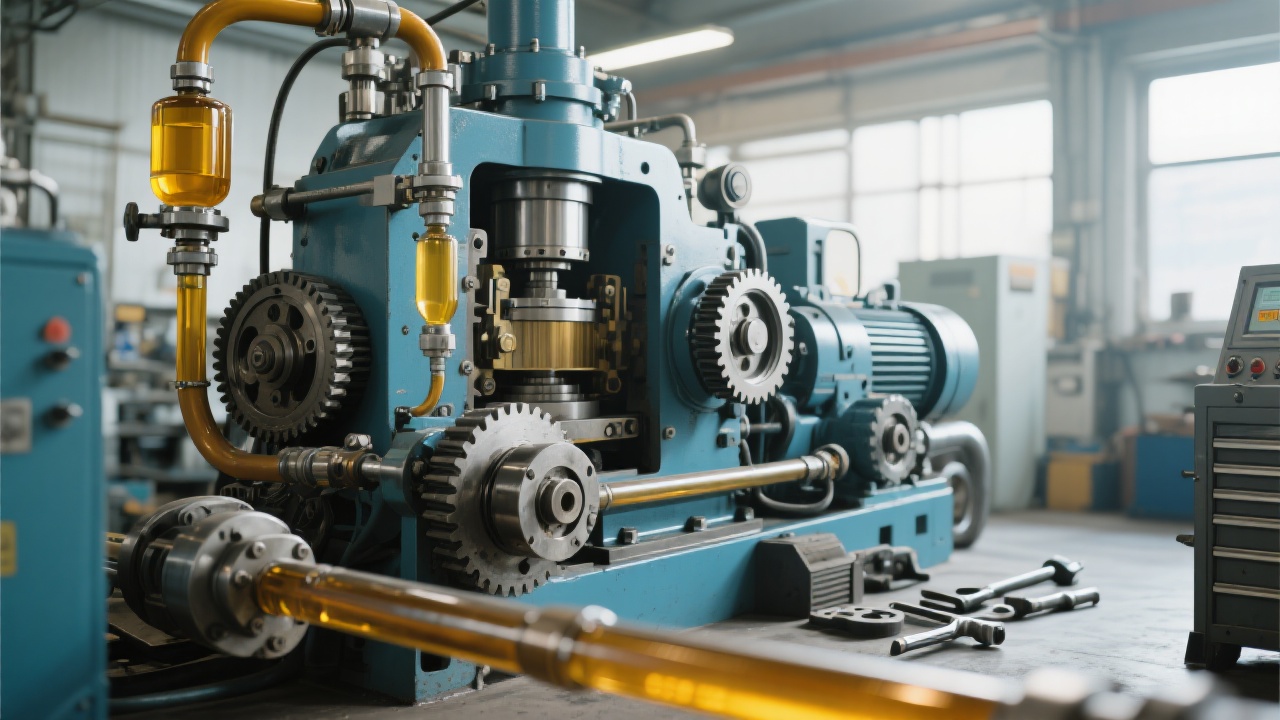

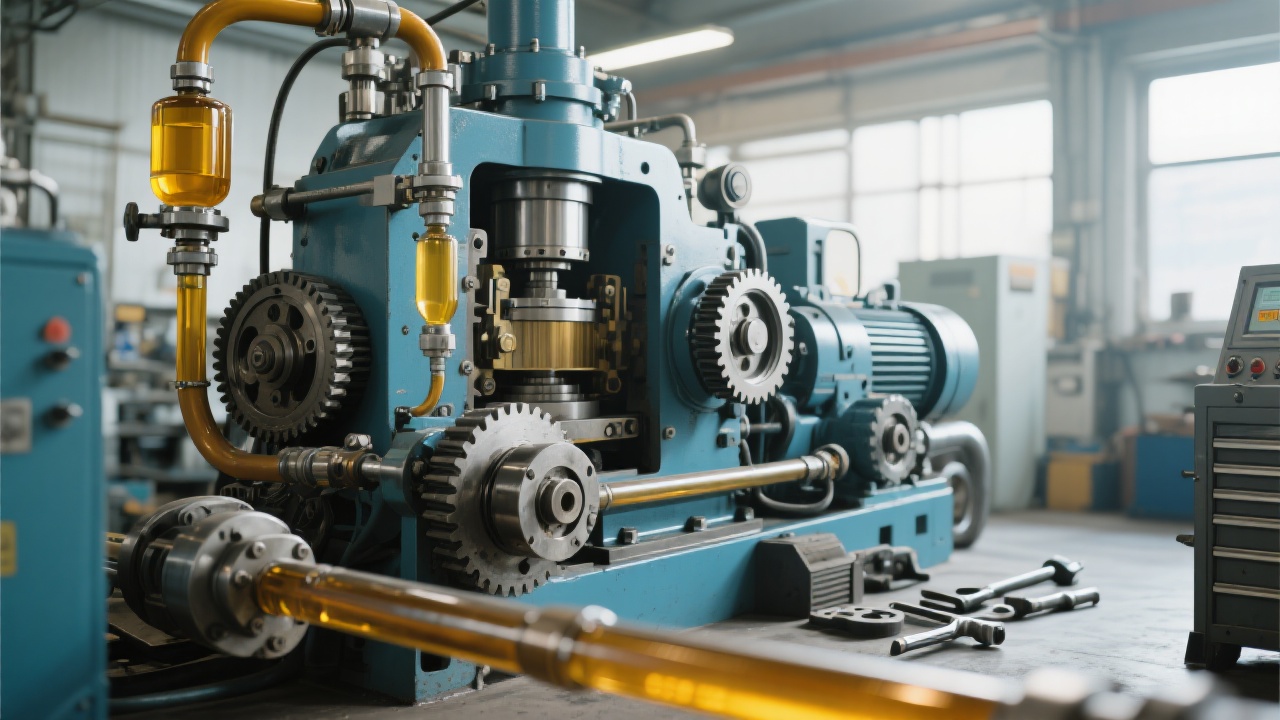

Comprehensive Maintenance Guide for Core Components of Palm Oil Press Equipment: Practical Tips to Extend Gear and Bearing Lifespan

2025-11-29

Technical knowledge

Mastering daily maintenance techniques for the core components of palm oil press equipment is essential for prolonging the lifespan of gears and bearings and ensuring stable production line operation. This article provides detailed guidance on maintenance cycles, lubrication methods, and cleaning frequencies for key parts such as gears, bearings, and pump assemblies. It integrates common fault identification—such as abnormal noises and pressure fluctuations—with emergency response procedures to help operators quickly diagnose issues and reduce downtime. Additionally, it covers practical aspects of water quality management, seal replacement, and electrical safety checks, delivering a systematic and actionable equipment health management plan for oil production enterprises to boost efficiency and maximize return on investment.

Essential Maintenance Guide for Palm Oil Press Core Components: Extending Gear and Bearing Lifespan

Operating and maintaining palm oil pressing equipment effectively hinges on the meticulous care of its core components — primarily gears, bearings, and pump assemblies. These parts are integral to production continuity and directly impact your energy efficiency and operational costs. For context, on average, the energy consumption per ton of crude palm oil pressed is approximately 22 kWh, emphasizing the need for minimal downtime and smooth equipment function.

Scheduled Maintenance: The Foundation of Longevity

Implementing a rigorous preventive maintenance schedule is critical to avoid unexpected breakdowns and costly repairs. Your maintenance routine should include:

- Gear Inspection & Lubrication: Inspect for wear or pitting every 500 operating hours. Apply high-quality industrial gear oil meeting ISO VG 220 standards, replenishing lubricant bi-monthly or after heavy operation cycles.

- Bearing Checks: Assess bearing temperature and vibration weekly. Replace lubricants every 1000 hours to prevent contamination and overheating.

- Pump Group Maintenance: Perform mechanical seal checks monthly to preclude leaks, ensure impellers are free of debris, and validate pump pressure levels stay within recommended thresholds (typically 4-6 bar for palm oil press pumps).

| Component |

Inspection Frequency |

Lubrication Cycle |

Key Checks |

| Gears |

Every 500 hours |

Every 2 months |

Wear, oil quality, gear backlash |

| Bearings |

Weekly temperature & vibration |

Every 1000 hours |

Noise, temperature, grease condition |

| Pump Group |

Monthly |

N/A (Seal replacement as needed) |

Seal integrity, pressure stability, impeller condition |

Early Fault Detection: Recognizing Warning Signs

Addressing issues promptly reduces downtime and extends equipment life. Key symptoms include:

- Unusual Noise: Increased gear chatter or bearing squeal often signals lubrication breakdown or misalignment.

- Pressure Fluctuations: Erratic pressure in the pump assembly may indicate seal wear or impeller damage.

- Vibration Spikes: Sudden increases in vibration amplitude can point to component imbalance or wear.

Water Quality Management & Auxiliary Maintenance

Water quality significantly affects pump longevity and hydraulic system performance. Employ these best practices:

- Use filtered water with TDS below 500 ppm to prevent sediment buildup.

- Replace seals and gaskets proactively every 6 months, or sooner if leakage is detected.

- Perform electrical inspections quarterly, verifying insulation resistance and grounding to prevent operational hazards.

Empowering Your Team: Training & Documentation

To maximize uptime, equip your operators and maintenance engineers with comprehensive training focused on:

- Systematic inspection checklists.

- Correct lubrication techniques and schedules.

- Fault identification and escalation protocols.

Maintaining clear, accessible records of maintenance activities is crucial. These not only help track equipment health trends but also support warranty claims if needed.