Ensuring the consistent performance of your palm oil pressing equipment is critical to maintaining high production efficiency and minimizing costly downtime. With machines operating in overseas production lines, expert guidance on daily maintenance and rapid troubleshooting empowers your engineering teams to preserve equipment longevity and optimize operational costs.

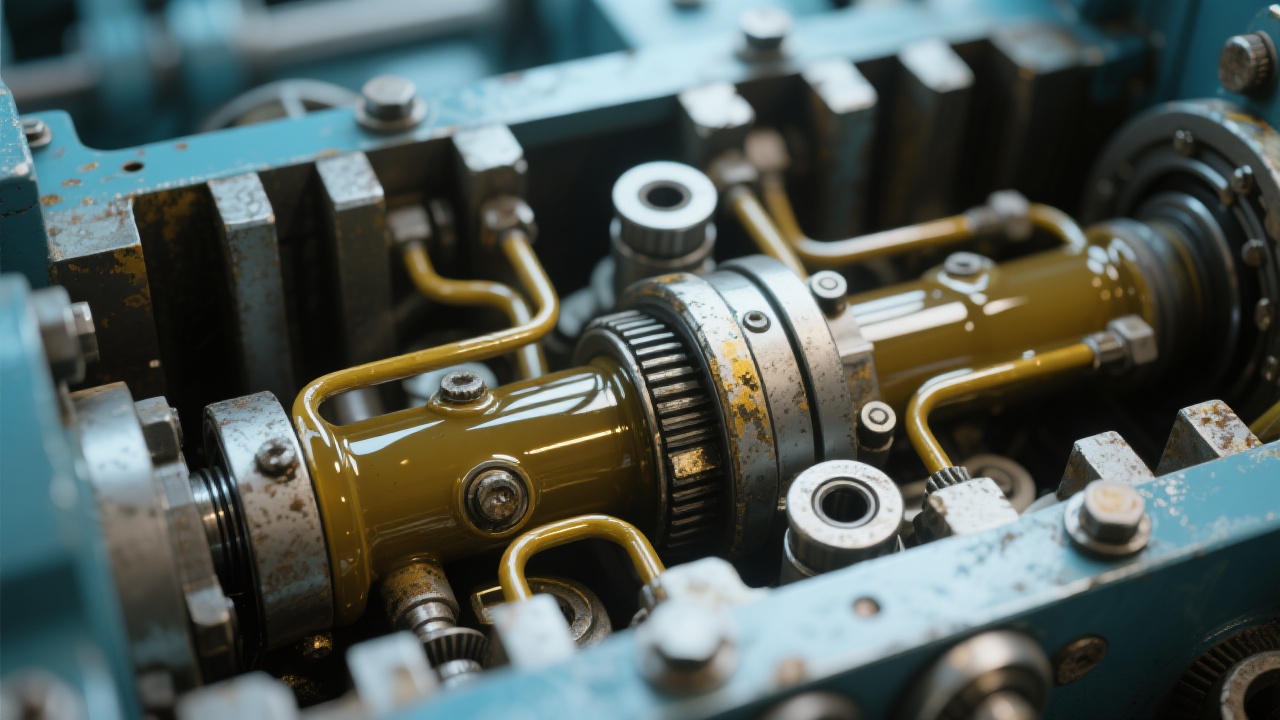

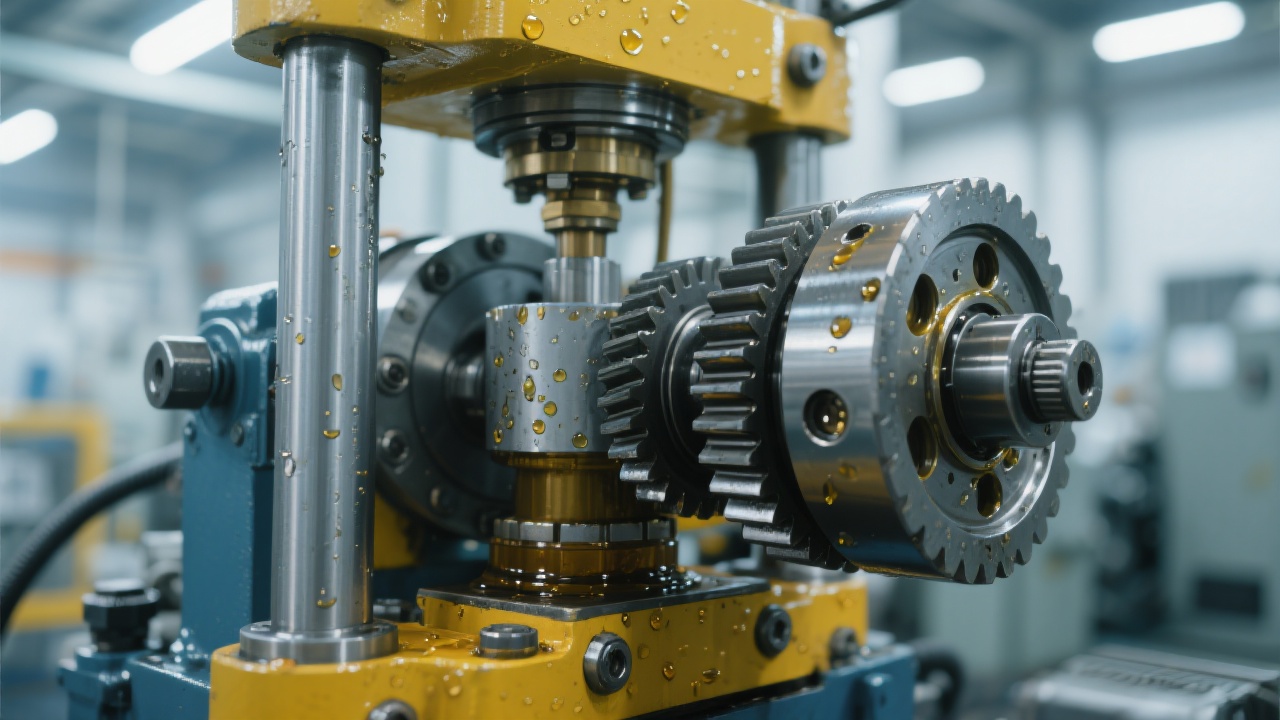

The heart of your palm oil press lies in components such as gears, bearings, and pump assemblies. Proper daily maintenance routines directly influence their operational lifespan – with well-maintained equipment reducing unexpected failures by up to 40% and decreasing energy consumption significantly. For instance, our data shows that a standard palm oil pressing unit consumes approximately 22 KWH per ton of oil extracted. Optimizing equipment efficiency through scheduled care not only lowers power usage but enhances throughput consistency.

| Component | Maintenance Interval | Main Tasks |

|---|---|---|

| Gears | Monthly | Lubrication check, visual wear inspection, alignment verification |

| Bearings | Biweekly | Cleaning, grease replenishment, temperature monitoring |

| Pump Assemblies | Weekly | Seal checks, flow rate verification, pressure adjustments |

Early recognition of abnormal equipment behavior is essential. Common fault indicators include unusual mechanical noises, such as grinding from gear misalignment, and pressure fluctuations exceeding 5% of nominal operating pressure. Implementing a systematic inspection protocol enables your team to intervene before minor issues escalate into production-stopping failures.

Follow this process: Detect noise or vibration → Check lubrication levels → Measure pressure output → Inspect seals and bearings → Apply corrective lubrication or replace components → Resume normal operation.

When faults occur despite preventive efforts, your operational team must act swiftly. Prioritize power shutdown of the affected unit, isolate hydraulic and pneumatic lines to prevent leaks, and follow lockout-tagout (LOTO) protocols. Use manufacturer-approved replacement parts for seals or worn components to ensure compliance with safety standards.

Beyond mechanical parts, optimal water quality is vital to avoid corrosion and contamination in hydraulic units. Regularly test water hardness and filter accordingly. Electrical installations demand periodic insulation resistance testing and secure grounding to mitigate risk of short circuits and electrical downtime.

Our technicians recommend keeping a detailed maintenance log and conducting operator training sessions quarterly to enhance maintenance discipline and early problem recognition. Adjust lubrication types seasonally to accommodate ambient temperature fluctuations, which can affect viscosity and equipment performance.

Secure your palm oil production line with trusted, worldwide maintenance expertise. Click here to learn more.