Mastering the daily maintenance techniques for the core components of palm oil pressing equipment is the cornerstone of extending equipment lifespan and ensuring efficient production. In this article, we'll delve into the maintenance cycles, lubrication methods, and cleaning frequencies of key components such as gears, bearings, and pump sets. We'll also combine practical experiences in identifying abnormal noises and judging pressure fluctuations to help operators quickly locate faults and take emergency measures. Additionally, it covers practical guides on water quality management, seal replacement, and electrical safety inspections, creating a systematic equipment health management plan to enhance production stability and return on investment.

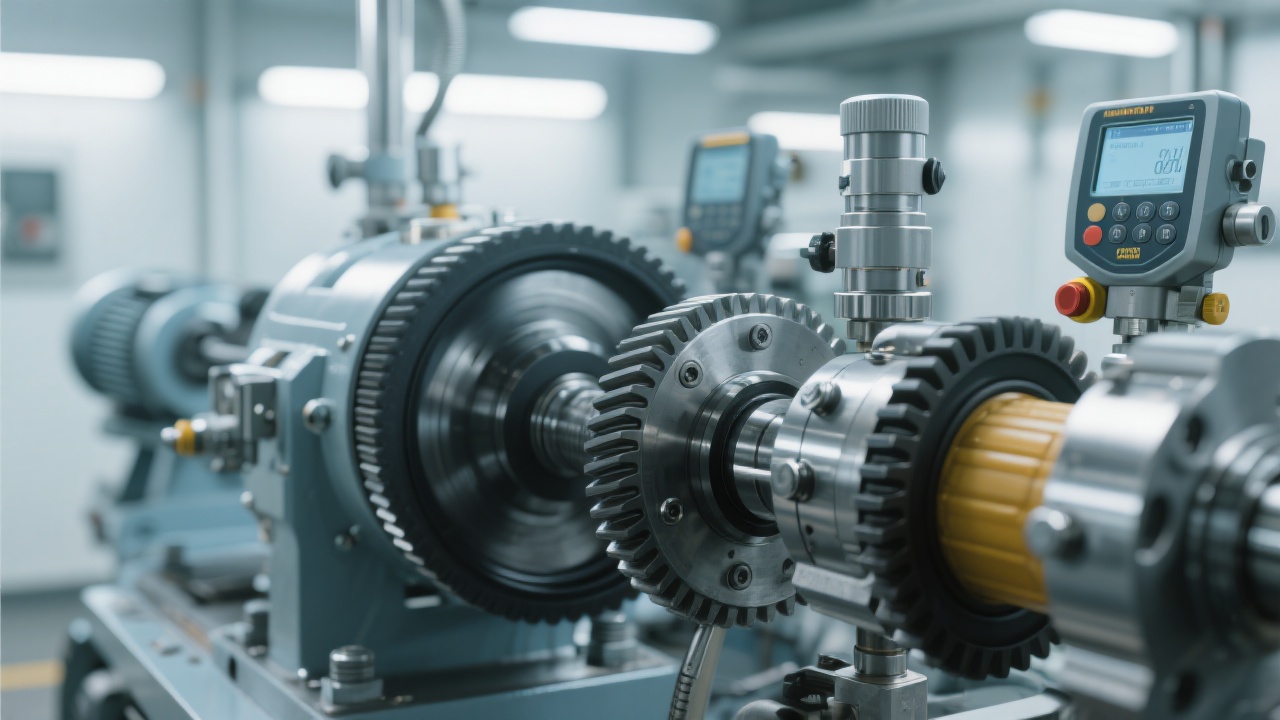

Let's break down the maintenance points of the gears, bearings, and pump sets of the press. For gears, lubrication should be carried out every 500 operating hours. Use high - quality gear oil with a viscosity of ISO VG 220 - 320. Clean the gears every 1000 hours to prevent the accumulation of debris. Bearings need lubrication every 300 hours, and the lubricant should be a high - performance grease with good anti - wear properties. Clean the bearings every 600 hours. As for pump sets, lubricate them every 400 hours and clean them every 800 hours. Here is a maintenance cycle table for your reference:

| Component | Lubrication Cycle | Cleaning Frequency |

|---|---|---|

| Gears | Every 500 hours | Every 1000 hours |

| Bearings | Every 300 hours | Every 600 hours |

| Pump Sets | Every 400 hours | Every 800 hours |

Regularly check these components for common problems such as wear, corrosion, and misalignment. For example, if you notice excessive wear on the gears, it may be due to improper lubrication or overloading.

Adopting the concept of preventive maintenance is crucial. By conducting regular inspections, you can avoid sudden停机. For instance, a monthly inspection of the entire palm oil production line can help you detect potential problems before they turn into major issues. Check the alignment of the components, the tightness of the bolts, and the condition of the lubricants. This way, you can prevent unexpected breakdowns and ensure continuous production.

When it comes to typical fault scenarios like abnormal noises or pressure fluctuations, here is a judgment flowchart and handling suggestions. If you hear abnormal noises from the equipment, first check the gears and bearings. Abnormal noises from gears may indicate lack of lubrication or tooth damage. For bearings, it could be due to improper installation or wear. If there is a pressure fluctuation in the system, check the pump sets and the pipelines. A pressure drop may be caused by a clogged filter or a leak in the pipeline. Here is a simple fault diagnosis flowchart:

Once you have identified the problem, take appropriate measures. For example, if it's a lubrication issue, replenish or change the lubricant immediately. If there is a mechanical damage, replace the damaged parts as soon as possible.

In addition to the maintenance of the core components, water quality control, seal replacement, and electrical safety inspections are also important. The water used in the equipment should have a pH value between 6.5 - 7.5 and low levels of impurities. Replace the seals every 1500 hours to prevent leakage. Conduct electrical safety inspections every quarter to ensure the safety of the operators and the normal operation of the equipment.

By following these maintenance tips and best practices in the industry, you can enhance the reliability of your palm oil pressing equipment and increase your production efficiency. And with Penguin Group's 2 - year warranty on core components and global technical support, you can rest assured that your equipment will always be in the best condition. Click here to get your exclusive maintenance plan now!