Maintaining palm oil pressing production lines is crucial for both the lifespan of the equipment and the efficiency of production. Regular and proper maintenance can significantly reduce the risk of unexpected breakdowns and downtime, ensuring a smooth and profitable operation. This article focuses on the daily maintenance essentials of Penguin palm oil pressing production lines, offering practical guidance for operators, maintenance engineers, and decision - makers.

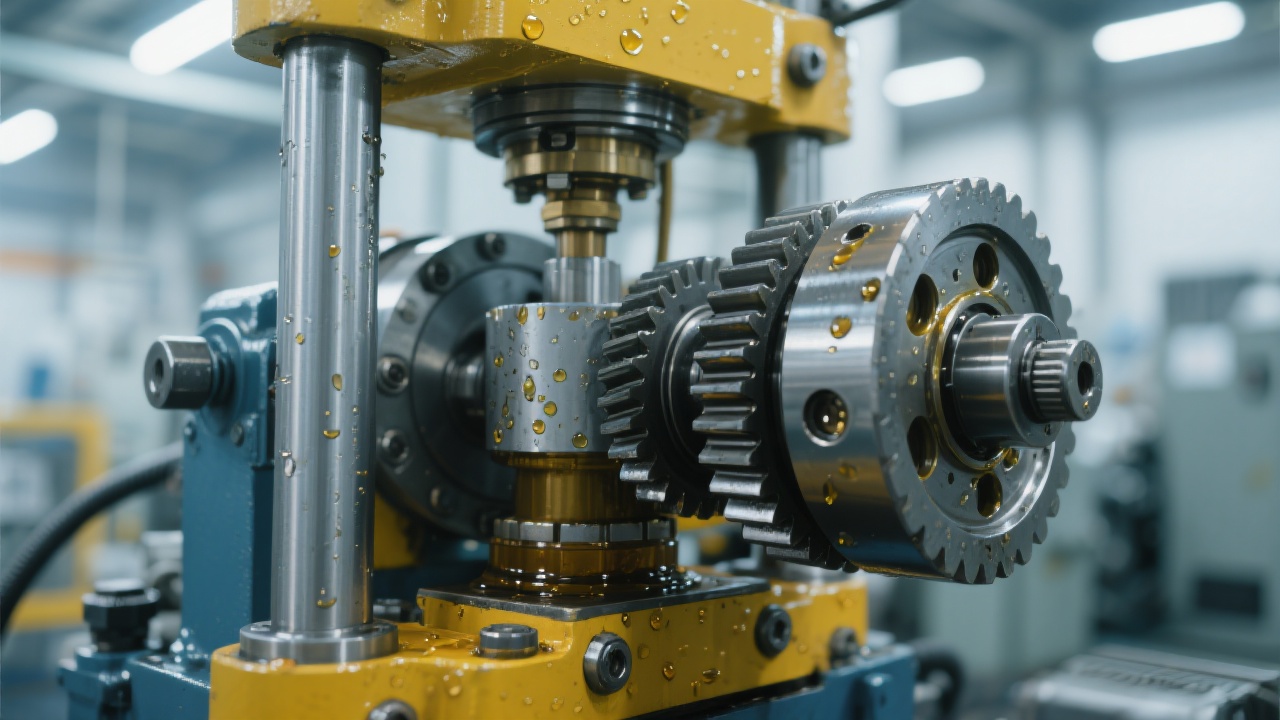

The core components of palm oil pressing equipment, such as gears, bearings, and pump sets, require meticulous care. For gears, a maintenance cycle of every 3 - 6 months is recommended. During maintenance, use high - quality lubricants to ensure smooth operation and prevent wear. The lubricant should be changed according to the manufacturer's instructions, usually every 1000 - 1500 operating hours. Cleaning the gears regularly, at least once a month, can remove debris and prevent corrosion.

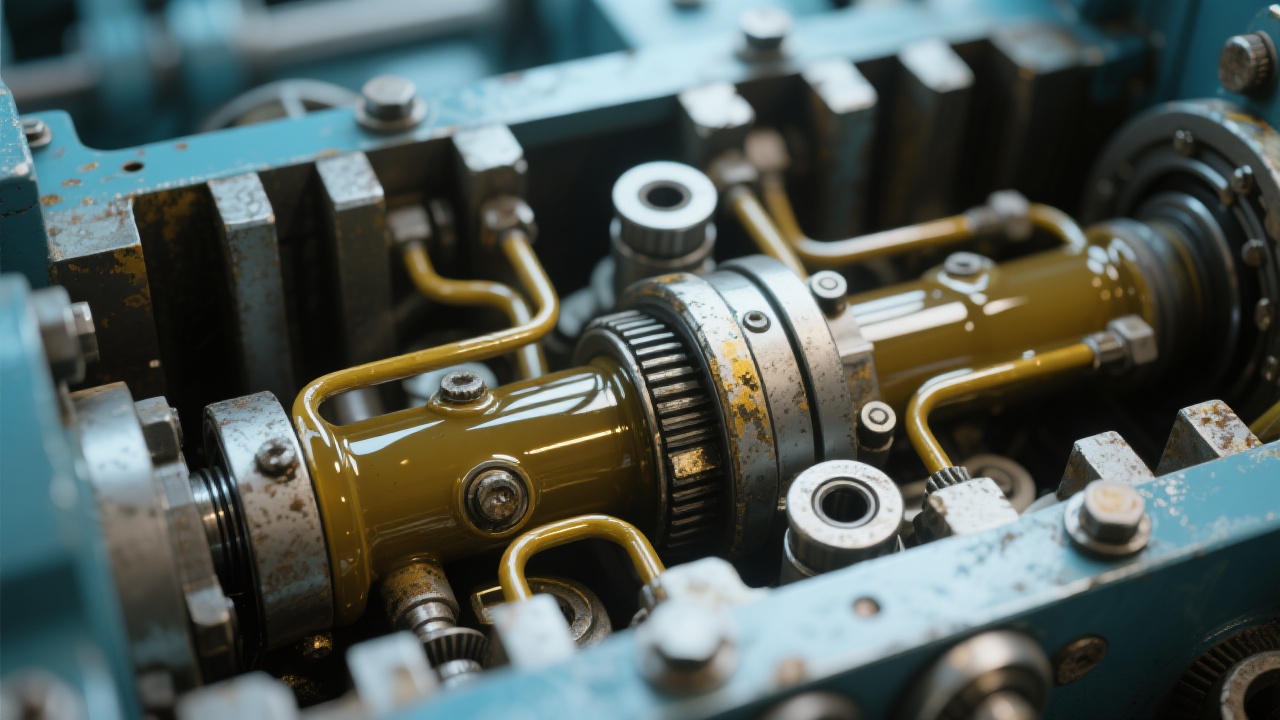

Bearings are another critical part. They should be inspected every 2 - 4 months. Lubrication is key to bearing performance, and the lubricant should be replenished every 500 - 1000 hours. Keep the bearings clean to avoid the ingress of dust and dirt, which can cause premature failure. Pump sets need to be maintained every 4 - 8 months. Check the pump's impeller, casing, and seals regularly. Clean the pump inlet and outlet to prevent blockages, and ensure proper alignment to avoid excessive vibration.

Preventive maintenance is the cornerstone of efficient equipment management. It involves regular inspections and early intervention to identify and address potential issues before they become major problems. A preventive maintenance schedule should be established based on the equipment's operating conditions and manufacturer's recommendations. For example, conducting monthly visual inspections, quarterly in - depth inspections, and annual comprehensive maintenance can help detect early signs of wear, corrosion, or misalignment.

Regularly checking for abnormal signals such as unusual noises, temperature changes, and pressure fluctuations can provide early warnings of potential failures. By intervening early, operators can avoid costly repairs and long - term production disruptions.

Recognizing common faults is essential for minimizing downtime. For example, if there is an abnormal noise in the equipment, it could indicate a problem with the gears or bearings. A sudden pressure drop in the pump set may suggest a blockage or a seal failure. By referring to the fault diagnosis flowchart (as shown in the figure below), operators can quickly identify the root cause of the problem.

Once a fault is identified, a well - defined emergency handling process should be followed. This includes isolating the faulty component, conducting a detailed inspection, and taking appropriate corrective actions. For minor faults, operators can often make on - the - spot repairs. For more serious issues, contacting the maintenance team immediately is recommended.

Auxiliary maintenance tasks are also important for the overall health of the equipment. Water quality management is crucial, as poor water quality can cause corrosion and scaling in the equipment. Regularly test the water quality and use water treatment agents if necessary. Seals should be replaced every 6 - 12 months to prevent leaks. Electrical safety checks should be carried out quarterly to ensure the safe operation of the equipment.

| Component | Maintenance Cycle | Lubrication Interval | Cleaning Frequency |

|---|---|---|---|

| Gears | 3 - 6 months | 1000 - 1500 hours | Once a month |

| Bearings | 2 - 4 months | 500 - 1000 hours | As needed |

| Pump Sets | 4 - 8 months | According to usage | Regularly |

If you are looking for professional maintenance services and technical support for your Penguin palm oil pressing production line equipment, look no further. Our team of experts is ready to provide you with comprehensive solutions to ensure the long - term efficient operation of your equipment. Contact us today at CTA - URL and let us help you achieve stable and high - quality production.