Operating a palm oil pressing production line demands more than just cutting-edge equipment — it requires systematic maintenance and proactive technical support to ensure continuous, efficient production. Overlooking maintenance of critical components such as gears, bearings, and pump assemblies can lead to unexpected downtime and increased operational costs.

This guide highlights the key maintenance routines, troubleshooting tips, and preventive strategies to empower your operations team with practical knowledge that supports stable machine performance and prolongs equipment lifespan.

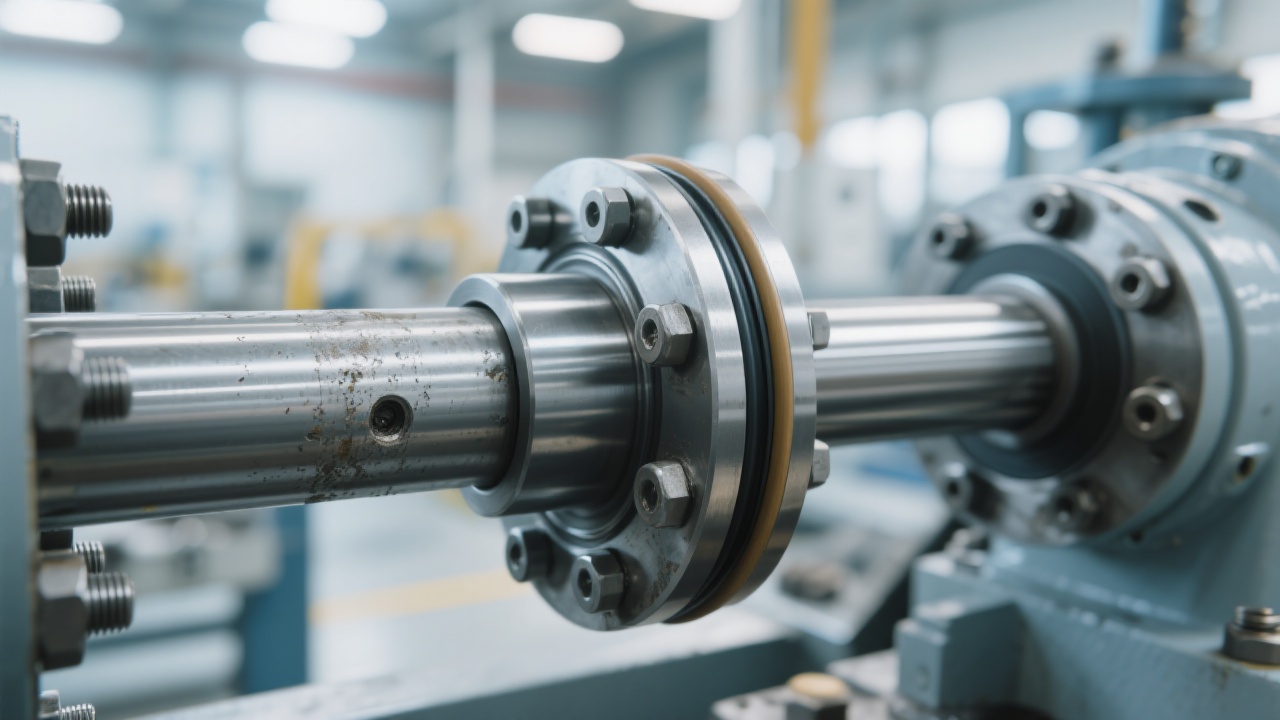

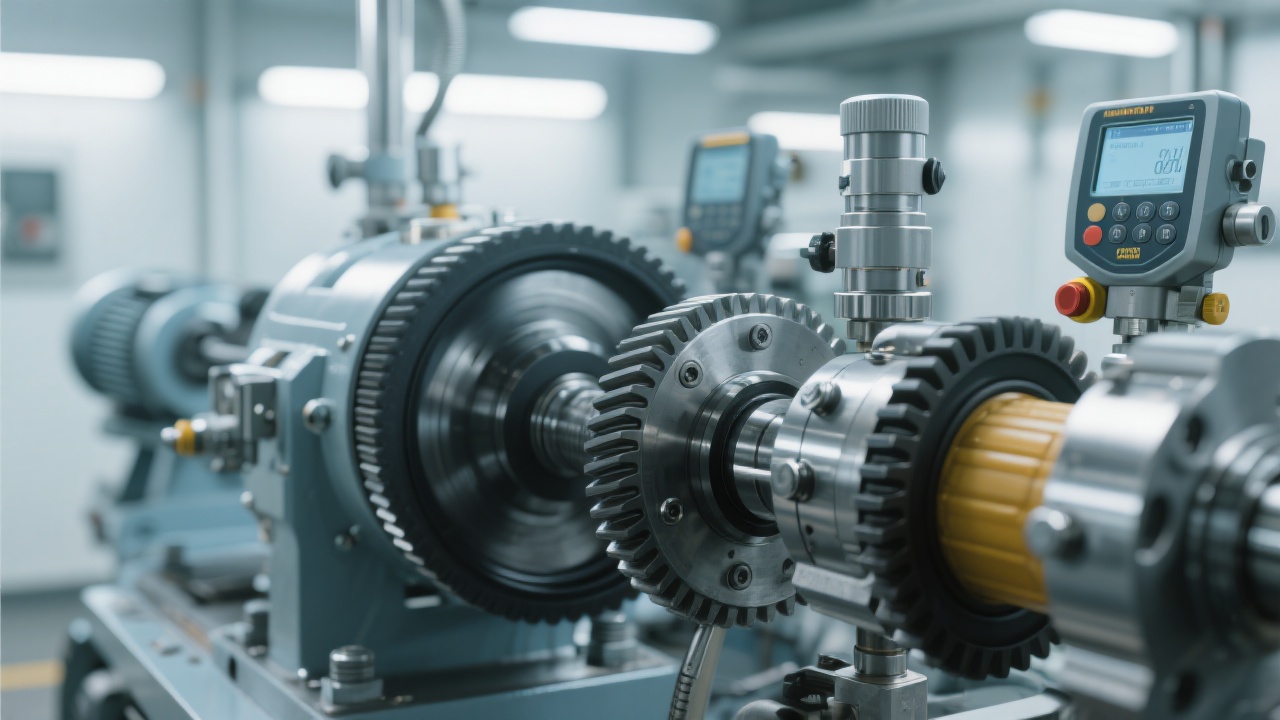

The backbone of your pressing line includes gears, bearings, and pumps — each requiring tailored care:

| Component | Recommended Maintenance Interval | Lubrication Method | Cleaning Frequency |

|---|---|---|---|

| Gears | Every 500 operational hours | High-grade synthetic gear oil, reapply before scheduled downtime | Monthly, or after heavy production cycles |

| Bearings | Every 300 operational hours; monitor vibration levels continuously | Grease lubrication with temperature stability; inspect seals before regreasing | Biweekly cleaning to prevent particulate buildup |

| Pump Assemblies | Inspect every 100 operational hours; full service quarterly | Use manufacturer-recommended pump oil and check filtration systems | Weekly wipe down and filter checks |

Adhering to a preventive maintenance schedule is vital in reducing unplanned shutdowns. This approach involves:

Installing oil quality sensors and vibration detectors can aid in real-time condition monitoring, providing alerts on deviations that may indicate impending faults. This proactive strategy can extend machine lifespan by up to 20% and decrease downtime by 15-25%, directly impacting operational throughput.

Identifying early warning signs is key to avoiding prolonged outages. Common fault indicators for palm oil pressing equipment include:

| Symptom | Possible Cause | Immediate Action |

|---|---|---|

| Unusual Grinding Noise | Worn gear teeth or bearing failure | Stop machine and inspect; replace affected parts |

| Pressure Fluctuations in Pump System | Clogged filters or leaking seals | Clean filters, check seals, and restore normal operation |

| Reduced Oil Output Quality | Water contamination or electrical malfunctions | Perform water quality test and electrical inspection |

Begin with symptom identification → Conduct physical inspection → Implement corrective maintenance → Resume production monitoring → Schedule follow-up preventive maintenance.

The performance of your palm oil pressing line also hinges on supportive maintenance activities:

Integrate these practices into a structured program that includes:

With a dedicated team following this plan, you can reduce unplanned downtime by up to 30%, optimize energy consumption since well-maintained machines require 10-15% less power, and improve overall throughput.

When unexpected issues arise, a clear and practiced emergency protocol is essential. Operators should:

Empowering your staff with both knowledge and authority to act swiftly can minimize losses and protect costly machinery.