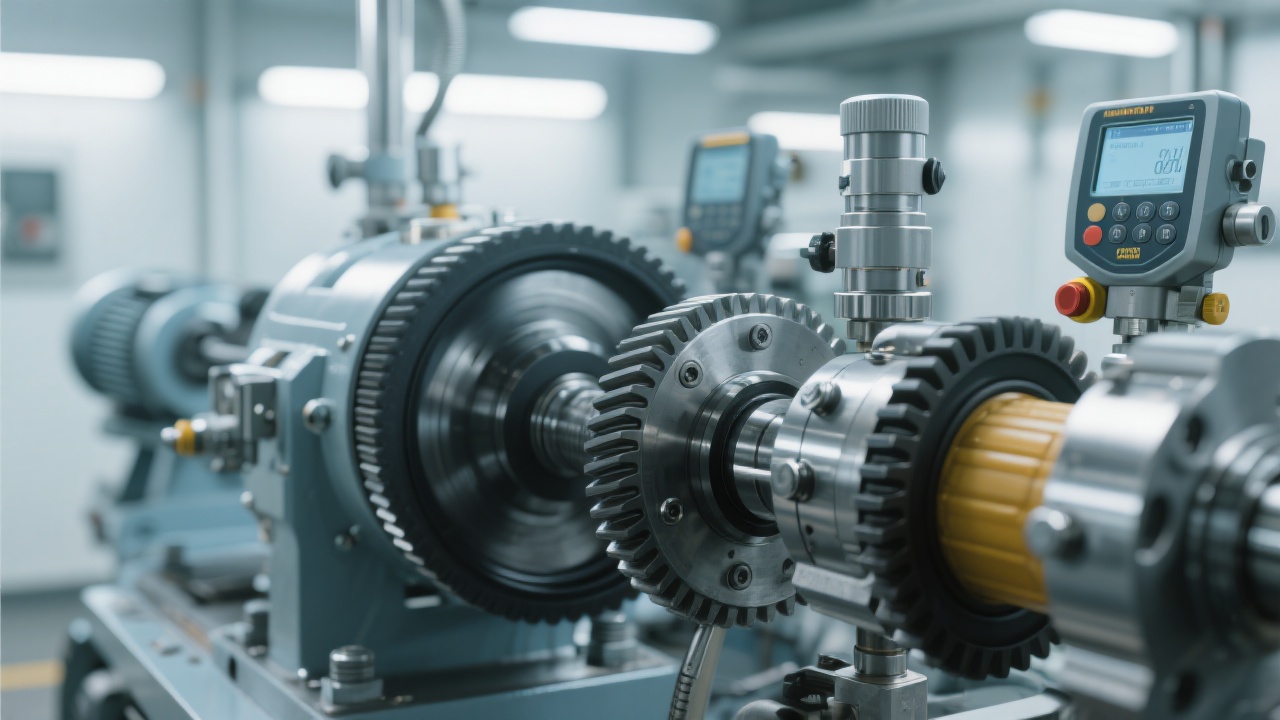

Maintaining your Penguin Palm Oil Press Production Line is crucial not only to extend equipment lifespan but also to maximize production efficiency. This guide provides practical, actionable tips on daily maintenance—focusing on key components such as gears, bearings, and pumps—while emphasizing preventive care, water quality management, seal replacement, and electrical safety inspections.

Proper upkeep of gears, bearings, and pump assemblies is paramount. Typically, lubrication cycles should range from every 500 to 1,000 operational hours, depending on the load and environmental conditions. Use high-quality lubricants—preferably synthetic oils recommended by equipment manufacturers—to reduce friction and wear. Cleaning must be performed at least weekly to prevent residue buildup, which could impair component efficiency.

For example, bearings operated under heavy load benefit from greasing every 750 hours, while gearboxes ideally receive oil changes quarterly. Clean these parts with lint-free cloths and approved solvents, avoiding any abrasive tools that can damage surfaces.

Implementing a *preventive maintenance approach* reduces unexpected downtime and costly repairs. Schedule regular visual inspections and condition monitoring—such as vibration analysis and thermal imaging—to detect early signs of wear or misalignment.

For instance, abnormal noise levels or unusual pressure fluctuations often indicate emerging faults. Establish a maintenance log noting these anomalies, enabling timely interventions before failures impact production.

Recognizing early warning signs is critical. Here’s a simple checklist for operators:

Once identified, follow a structured emergency response protocol: isolate the affected component, perform diagnostic checks, and replace or repair the faulty parts. This limits production loss to under two hours in most cases.

Consistent water quality drastically affects equipment performance, especially in cooling and hydraulic systems. Monitor key parameters biweekly including pH (ideal range: 6.5–8.5), hardness (below 150 mg/L CaCO₃), and suspended solids concentration (less than 50 mg/L).

Utilize inline water treatment such as filtration and softening units to maintain these standards. Prevent scale buildup and corrosion, which can cause premature pump failures.

| Maintenance Task | Recommended Frequency | Notes |

|---|---|---|

| Gear Lubrication | Every 750 hours | Use synthetic oil for high-load gears |

| Bearing Greasing | Bi-monthly or 500 hours | Monitor temperature; do not over-grease |

| Water Quality Check | Every 2 weeks | Test pH, hardness, and solids |

| Seal Inspection & Replacement | Every 3 months or if leakage detected | Use OEM-approved seals only |

Worn seals can cause leakage and contamination, resulting in costly downtime. Replace seals every 3,000 operating hours or immediately if visual inspection shows cracks or deformation. Recommended procedure:

Overlooking electrical safety can lead to severe accidents and production halts. Inspect wiring insulation integrity every six months and verify ground connections. Use thermal imaging cameras to detect hot spots that could indicate faulty circuits.

In addition, ensure emergency stop functions are fully operational and clearly marked. Regular training for operators on electrical safety protocols enhances overall plant security.