As an operator or engineer managing palm oil extraction, swiftly diagnosing machine anomalies like unusual noises and pressure fluctuations is critical to maintaining uninterrupted production and optimizing equipment lifespan. Here, you'll gain actionable insights drawn from Penguin Group's decade-long maintenance expertise, focusing on gearboxes, bearings, pump modules, and essential auxiliary components. Integrate these maintenance protocols and troubleshooting strategies to reduce downtime, lower operational costs, and ensure safer, more efficient palm oil processing.

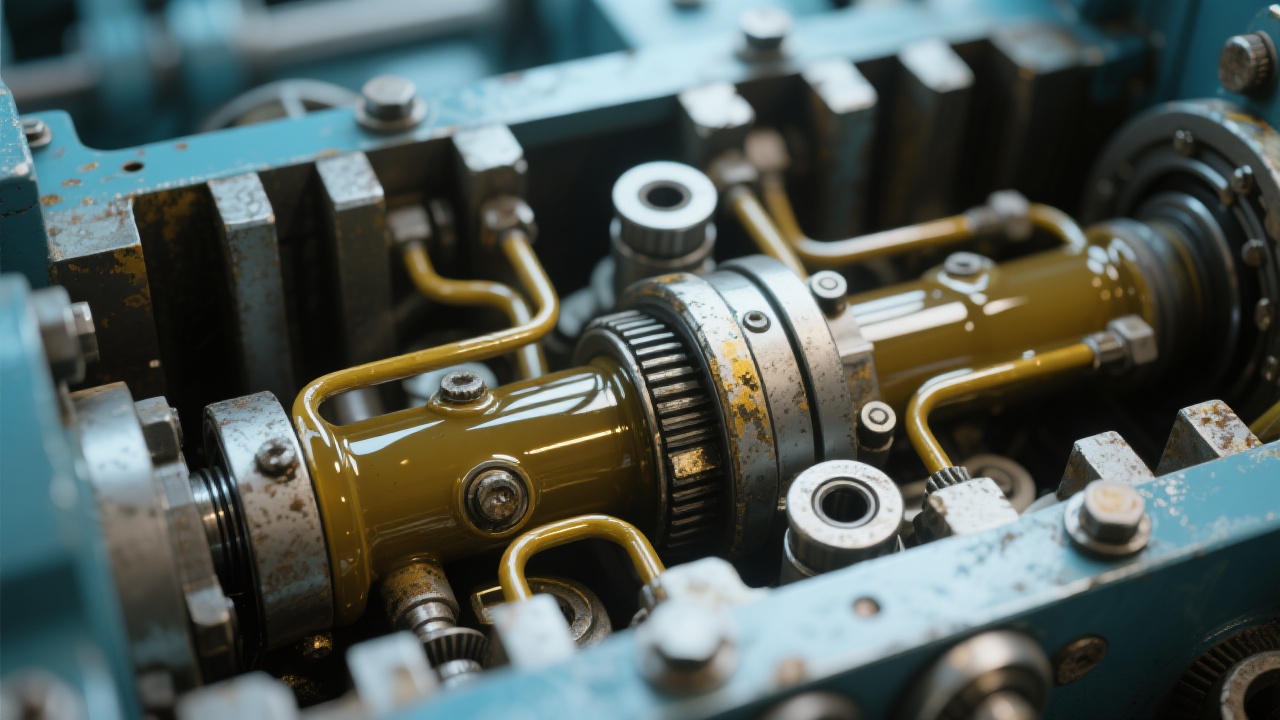

Two of the most frequent issues encountered during palm oil pressing are abnormal machine noise and pressure instability. Noise often signals mechanical friction, misalignment, or component wear. Pressure fluctuations may indicate blockages, pump inefficiencies, or hydraulic seal leaks.

| Symptom | Possible Cause | Impact on Production |

|---|---|---|

| Grinding or Rattling Noise | Worn bearings or gears, insufficient lubrication | Reduced throughput due to mechanical degradation; risk of abrupt failure |

| Spiking or Dropping Pressure | Pump cavitation, clogged filters, seal leakage | Oil yield reduction, potential hydraulic damage, increased energy consumption |

Data from industry benchmarks show that unaddressed pressure fluctuations can increase steam consumption by up to 8% and electrical power usage by 7%, impacting operational cost significantly.

Start by localizing the source of abnormal noise with targeted sensor readings and visual checks. Next, correlate noise intensity with pressure readings from the hydraulic system. A connected flowchart will guide your diagnosis efficiently:

Apply corrective actions based on findings: replace or realign worn gears, replenish or change lubricants at defined intervals, clean or swap hydraulic filters, and tighten or replace faulty seals.

Preventive maintenance is your strongest line of defense. Below are key guidelines focused on three critical parts:

| Component | Maintenance Interval | Lubrication Type & Frequency | Key Checks |

|---|---|---|---|

| Gearbox | Every 3 months | Heavy-duty gear oil, replenish monthly | Visual gear wear, oil contamination, temperature rise |

| Bearings | Monthly | High-performance grease, reapply biweekly | Noise levels, shaft alignment, grease residue checks |

| Pump Modules | Every 6 months | Hydraulic oil per OEM specs, oil level monthly check | Seal integrity, noise, flow rate consistency |

Alongside mechanical maintenance, water quality management is vital—contaminants accelerate corrosion affecting seals and metal surfaces. Regularly replace density- and hardness-monitoring filters. Additionally, inspect electrical connections and control systems for shorts or overloads to safeguard against unexpected failures.

Adopting a scheduled preventive maintenance approach reduces average downtime by 30-40% and extends machinery operational lifespan by up to 25%. Early detection of wear lowers unexpected repair expenses, enabling budget predictability and maintaining steady output.

To embed these best practices, develop maintenance logs linked to condition monitoring sensors. Investing in predictive analytics platforms yields real-time alerts, allowing intervention before faults escalate.