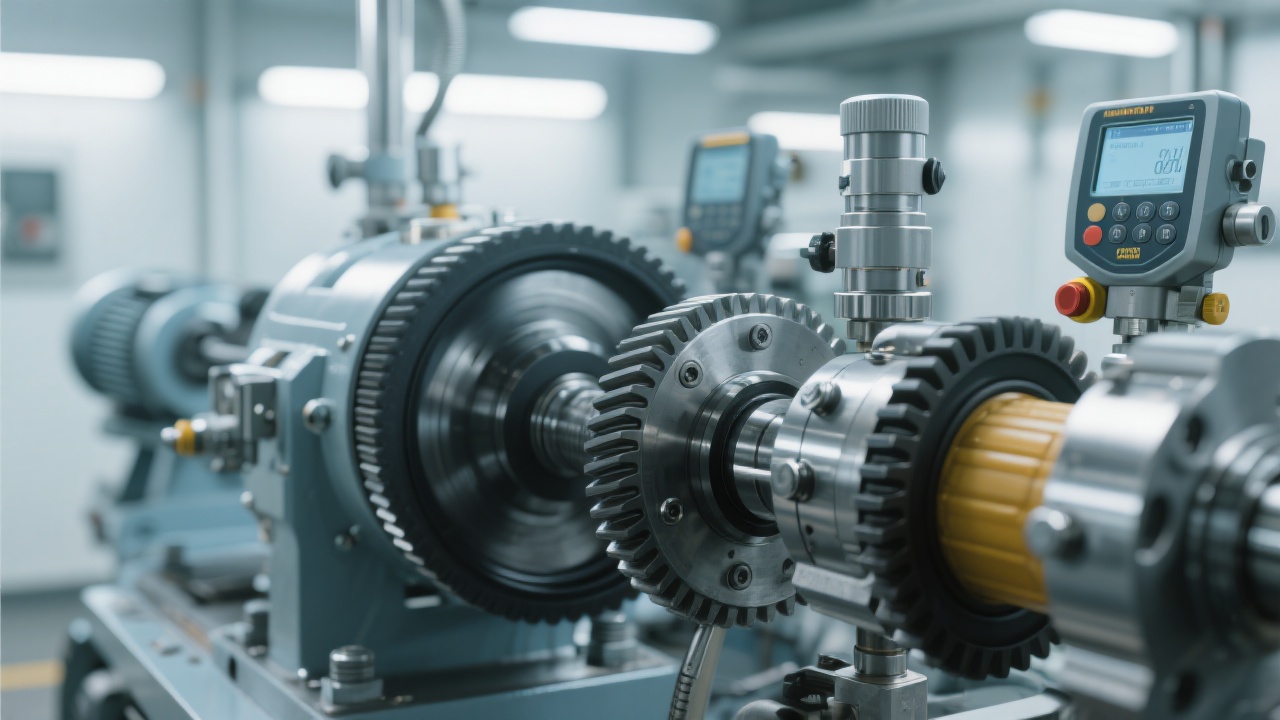

The longevity and efficiency of palm oil pressing equipment fundamentally depend on effective routine maintenance. Penguin Brand’s palm oil pressing machines are engineered for high productivity, yet without a systematic care regimen, even the most advanced components degrade faster, leading to unexpected downtime and production losses. This technical guide presents a comprehensive overview of key maintenance aspects targeted at operators, maintenance engineers, and plant managers, focusing on critical parts like gears, bearings, and pump assemblies.

Maintaining core components within recommended intervals ensures continuous optimal performance. For instance, precision gears require inspection and lubrication every 500 operating hours, utilizing synthetic gear oils with an ISO VG rating of 220 to reduce wear and thermal stress. Bearings should be greased every 300 hours with high-quality lithium-based grease, while confirming no signs of overheating or corrosion. Pump groups must undergo cleaning and seal checks on a monthly basis to prevent clogging and leakage.

| Component | Maintenance Interval | Lubrication/Cleaning Type |

|---|---|---|

| Gears | Every 500 operating hours | Synthetic gear oil ISO VG 220 |

| Bearings | Every 300 operating hours | Lithium-based grease |

| Pump Assembly | Monthly | Thorough cleaning & seal inspection |

Beyond scheduled care, adopting a preventive maintenance mindset is critical. This involves routine equipment inspections, monitoring vibration levels, and oil analysis to detect early signs of degradation. Establishing a preventive schedule reduces sudden failures, enabling preemptive part replacements and system tuning, crucial for avoiding costly production halts.

Early recognition of abnormal signs such as unusual noise, pressure fluctuations, or temperature spikes is essential. In particular, anomalous gear grinding sounds often indicate insufficient lubrication, while abrupt pump pressure drops may signal seal failure or clogging. The following flowchart aids in rapid fault identification and corrective action planning, minimizing downtime.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Grinding Noise from Gears | Low lubrication or gear wear | Immediate lubrication; inspect gears for replacement |

| Pump Pressure Drop | Seal failure or clogged intake | Flush system; replace seals promptly |

| Bearing Overheating | Insufficient greasing or misalignment | Re-grease; realign shafts if needed |

Efficient water quality management is crucial, as impurities accelerate component corrosion and clog filters. Routine testing of inlet water against turbidity and pH standards (aiming for turbidity < 2 NTU and neutral pH around 7) is advised. Replacement of sealing materials should follow manufacturer timelines, typically every 6-12 months, or sooner if leakages appear. Additionally, electrical system inspections—including grounding verification and insulation resistance tests—must be scheduled biannually to prevent hazards and ensure control panel reliability.

The integration of maintenance management software can further optimize scheduling, record-keeping, and predictive analytics, tailoring upkeep strategies to actual operating data and reducing unplanned repairs.

A notable example at a Southeast Asian palm oil mill involved sudden pump seal failure mid-shift. Thanks to an established emergency protocol and on-site spare parts stock, the technical team was able to replace the seals within 2 hours, restoring full capacity without major loss. This underscores the value of comprehensive maintenance strategies encompassing preventive and emergency elements.