In today’s competitive palm oil market, efficiency, quality, and adaptability are paramount. The Penguin Group’s latest small-scale palm oil production line redefines industry standards by integrating advanced cold and hot pressing technologies with premium-grade 304 stainless steel components. Engineered for versatility and performance, these modular production lines meet the diverse demands of processing facilities, food and beverage manufacturers, and agricultural enterprises, delivering maximum oil yield without compromising product integrity.

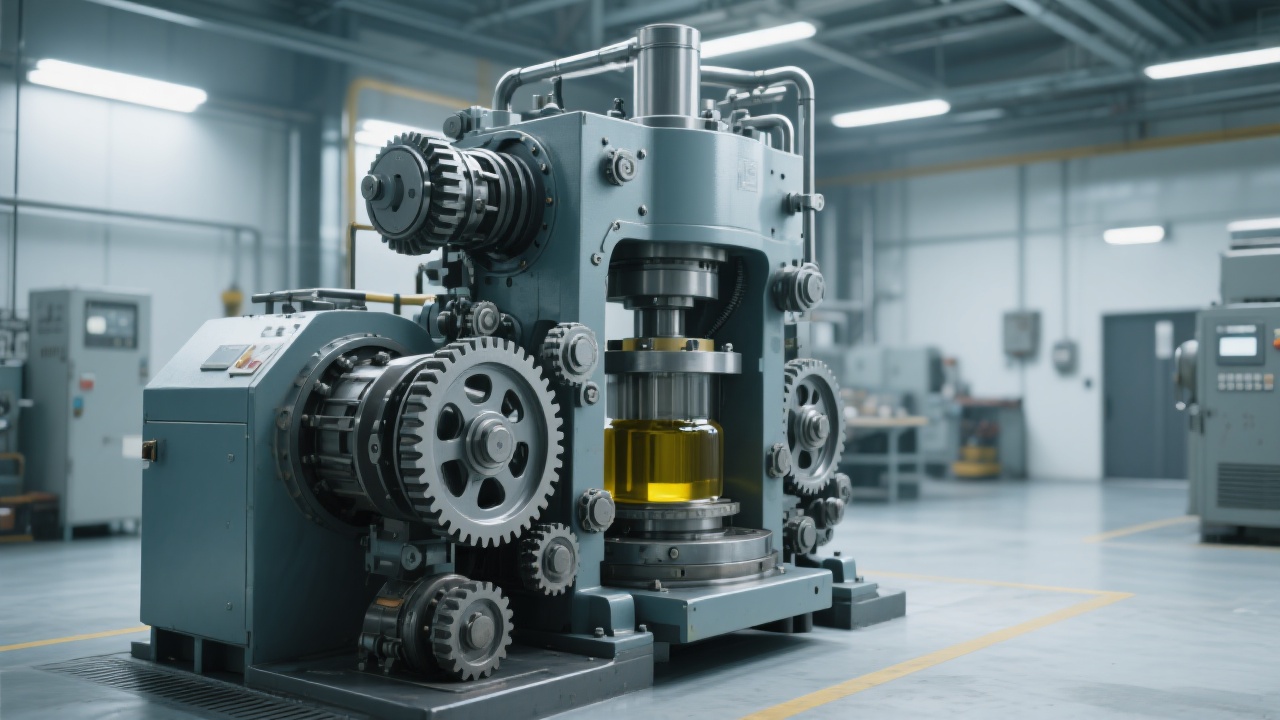

The Penguin production line employs an innovative combination of cold and hot pressing techniques that significantly enhance oil extraction efficiency. Cold pressing preserves the natural bioactive compounds and antioxidants, ensuring superior nutritive value and flavor profile, while hot pressing optimizes yield by effectively breaking down the fibrous palm fruit material. Field data indicates this dual-process can increase the overall oil extraction rate by up to 20% compared to traditional single-method presses.

This synergy between technologies ensures oil quality remains premium-grade, meeting stringent industry specifications and consumer expectations. Such cutting-edge pressing methods are especially advantageous for small to medium-sized enterprises looking to maximize output without the expense of large-scale facilities.

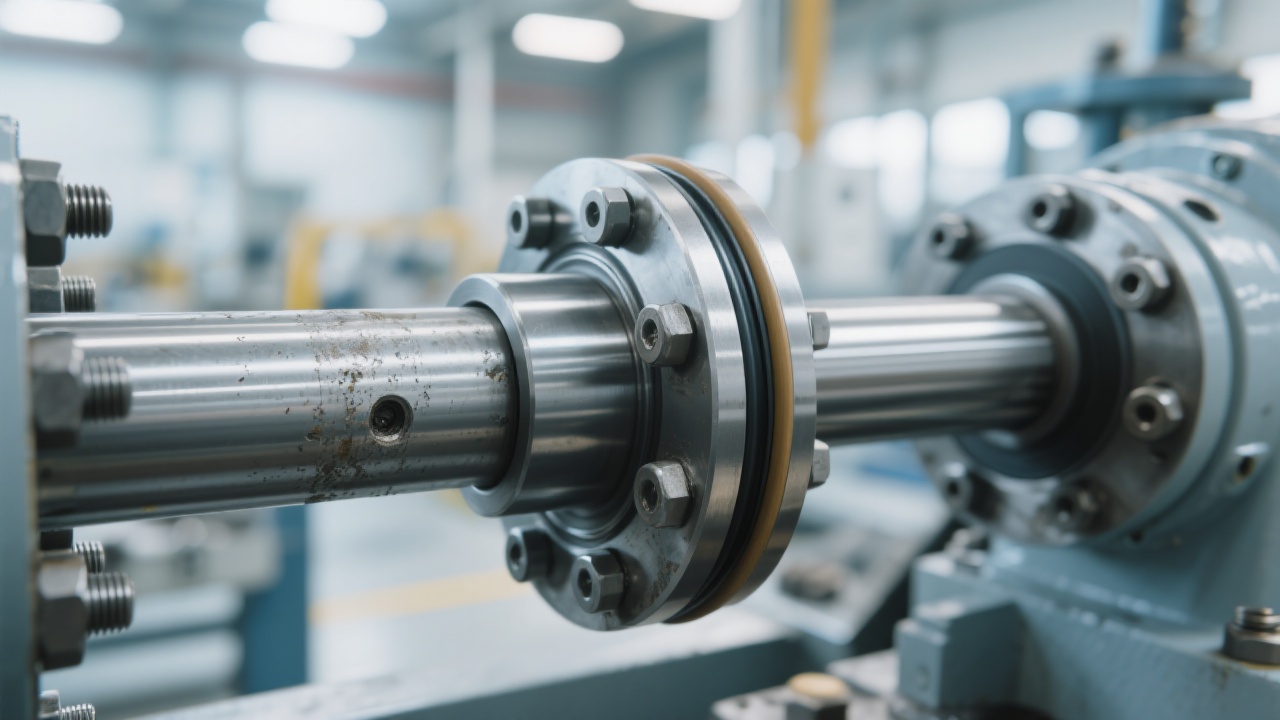

The core framework and critical parts of the Penguin palm oil line consist of 304 stainless steel, renowned for its corrosion resistance and hygienic properties, making it ideal for food-grade processing environments. The integration of internationally recognized brand components—such as precision motors, high-efficiency pumps, and stable control systems—ensures operational reliability and lowers maintenance requirements.

This meticulous component selection leads to extended machine longevity, minimizing downtime and total cost of ownership. The robustness of the equipment supports continuous operation in various environmental conditions, securing production consistency.

Penguin’s palm oil production lines prove adaptable for numerous sectors, including manufacturing plants, food and beverage factories, and agricultural farms. This diversity accommodates differing raw material sources, processing scales, and product requirements. For instance, food manufacturers benefit from equipment capable of producing pure, additive-free palm oil, while agricultural operations leverage the system to create value-added products from harvested crops.

The equipment’s modular design allows easy adjustment of capacity and processing parameters, making it feasible for enterprises to scale operations based on market demand.

Understanding the critical role of brand identity and operational specificity, Penguin Group offers extensive customization options, including exterior color schemes, logo integration, and bespoke packaging solutions. This personalization not only enhances brand visibility but also streamlines plant aesthetics, contributing to more efficient workflow organization.

Customized configurations accommodate client preferences for processing capacity, automation level, and auxiliary functionalities, ensuring that each production line aligns precisely with the enterprise’s operational priorities and compliance requirements.

The Penguin palm oil production lines strictly adhere to the ISO9001:2000 quality management system, underscoring the company’s commitment to product reliability and customer trust. Comprehensive mechanical inspections and real-time video monitoring during manufacturing ensure that every unit surpasses quality benchmarks.

These rigorous controls result in high-performance equipment characterized by durability, operational safety, and consistency, significantly reducing the risk of production interruptions and quality variances.

| Specification | Details |

|---|---|

| Material | 304 Stainless Steel |

| Oil Extraction Rate | Up to 20% higher than conventional |

| Industry Standards | ISO9001:2000 Certified |

| Customization | Color, Logo, Packaging, Capacity |

Penguin Group elevates client experience through full-spectrum services encompassing professional installation, tailored production line design, and ongoing technical support. Skilled engineers are dispatched worldwide to ensure seamless setup and calibration, optimizing machine performance from day one.

This customer-centric approach reduces implementation risks and accelerates time-to-market for palm oil products, fostering stronger business outcomes.

Penguin Group’s palm oil machinery has been exported to over 25 countries across Asia, Africa, and Latin America, where it consistently garners praise for operational efficiency and robust construction. Clients report average increases of 15-20% in oil output within the first six months of use, translating into tangible gains in profitability.

One notable case includes a Tanzanian mid-sized food processor that, after integrating the Penguin custom line, expanded its product range and entered new export markets owing to enhanced product quality and consistency.

Whether launching a new palm oil venture or upgrading existing operations, choosing a production line built to exact specifications and reliable performance is critical. Penguin Group’s small-scale, customizable palm oil production lines stand out as smart investments that combine technological innovation, operational flexibility, and solid after-sales support.

Embrace a partnership with the industry leader to elevate your production capabilities, boost product quality, and grow your brand in the global palm oil market.

Discover How Your Custom Palm Oil Line Can Boost Efficiency and Profits Today