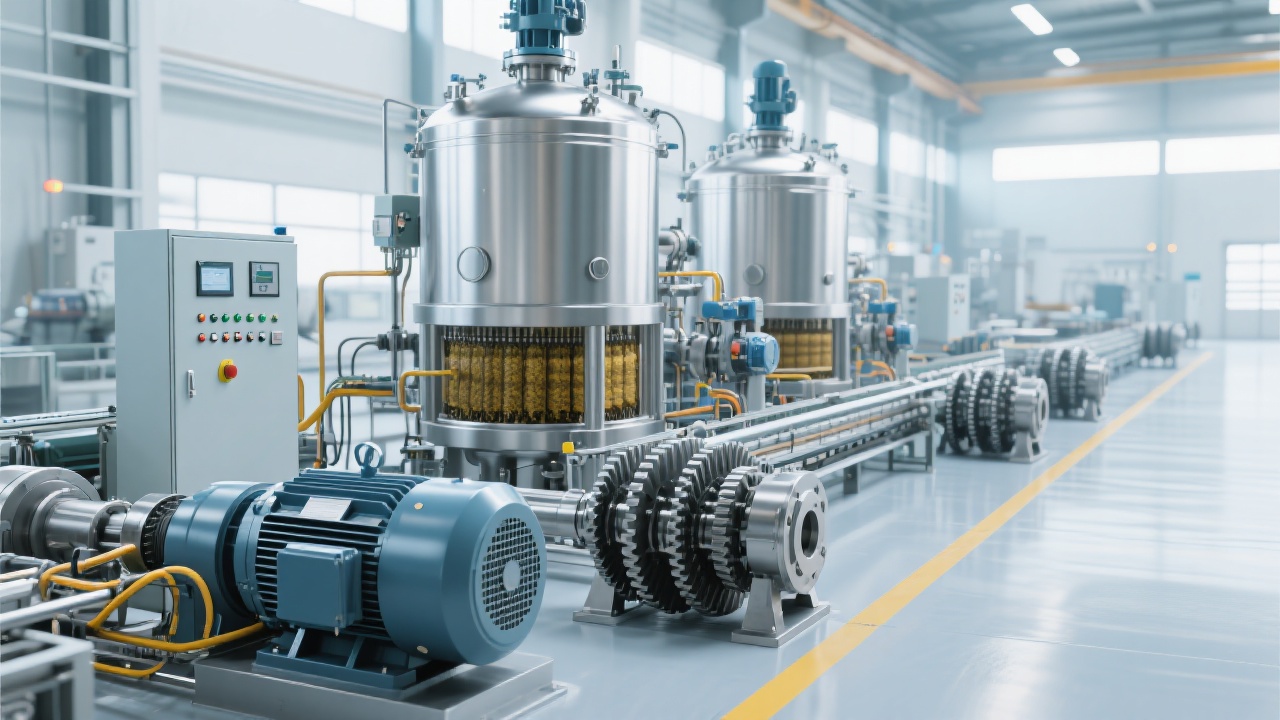

PLC (Programmable Logic Controller) automation has emerged as a game - changer in the palm oil production line. It serves as the central nervous system, orchestrating every step of the palm oil pressing process. By integrating advanced control algorithms and real - time data processing, PLC systems ensure seamless operation from the initial stage of raw material intake to the final product output.

In the feeding stage, the PLC system precisely controls the amount of raw palm fruits entering the production line. It uses sensors to detect the level of the raw material hopper and adjusts the feeding speed accordingly. This ensures a continuous and stable supply of raw materials, preventing over - feeding or under - feeding situations.

During the pressing process, the PLC system optimizes the pressing force and time. It monitors the pressure inside the press through pressure sensors and adjusts the pressing parameters in real - time. For example, if the pressure is too low, the system will increase the force to ensure maximum oil extraction.

In the oil - water separation process, the PLC system controls the flow rate and temperature. By using flow and temperature sensors, it can accurately separate the oil and water, improving the quality of the final palm oil product.

Typical industrial sensors such as pressure, temperature, and flow sensors play a crucial role in the palm oil production line. Pressure sensors are usually installed at the pressing chamber to monitor the pressing force. Temperature sensors are placed at key points like the oil - water separator to ensure the optimal separation temperature. Flow sensors are used at the inlet and outlet of various components to measure the flow rate of materials. These sensors provide real - time data on the equipment status, enabling operators to make timely adjustments.

Data collection and remote monitoring are essential for preventive maintenance. The PLC system collects data from all sensors and stores it in a database. Operators can access this data remotely through a dedicated monitoring platform. By analyzing the data, they can detect potential equipment failures in advance and take preventive measures, reducing non - planned downtime. For example, if the temperature of a certain component is rising abnormally, the system can issue a warning, allowing maintenance personnel to check the equipment before a major breakdown occurs.

Automation in the palm oil production line has brought significant productivity growth and energy efficiency improvement. According to industry data, with the application of PLC automation, the unit energy consumption can be reduced by up to 30%. For instance, the electricity consumption per ton of palm oil can be reduced from 30 KWH to 21 KWH. Moreover, the response speed of fault early - warning has been increased by 50%, which means that potential problems can be addressed more quickly, minimizing production losses.

When small and medium - sized oil enterprises are upgrading their equipment, they need to carefully select the PLC system. Factors such as system reliability, expandability, and cost - effectiveness should be considered. In addition, personnel training is also crucial. Operators should be trained on how to operate and maintain the PLC system, as well as how to analyze the data collected by the sensors. This will ensure the long - term and efficient operation of the automated production line.

Are you looking to upgrade your palm oil production line? Penguin Palm Oil Pressing Production Line offers global service + 2 - year warranty and a flexible daily production capacity ranging from 5 to 2000 tons. Don't miss this opportunity to enhance your production efficiency. Click here to learn more.