In the palm oil production industry, the lifespan and efficiency of production equipment are crucial factors that directly impact a company's bottom line. This article delves into the preventive maintenance strategies for palm oil production equipment, offering valuable insights and best practices to help businesses achieve stable and efficient production.

Regular daily maintenance is the cornerstone of extending the lifespan of palm oil production equipment and enhancing production efficiency. According to industry statistics, proper maintenance can reduce equipment downtime by up to 30% and increase production efficiency by 20%. For example, in a well - maintained palm oil production line, the steam consumption per ton of oil can be kept below 300kg, which significantly reduces energy costs.

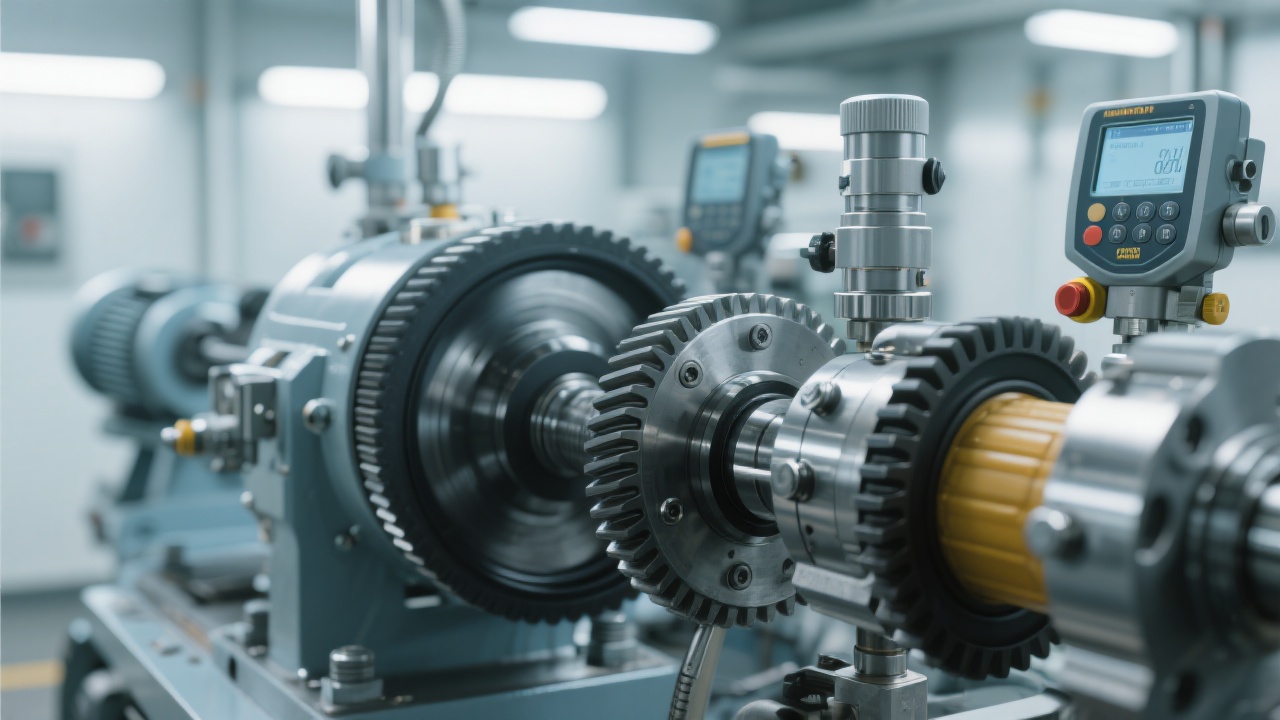

Gears are one of the most critical components in palm oil pressing equipment. The recommended maintenance cycle for gears is every 3 - 6 months. During maintenance, it is essential to clean the gears thoroughly and apply high - quality lubricants. The lubrication method should follow the manufacturer's instructions, usually using oil bath lubrication or splash lubrication. The cleaning frequency should be at least once a month to remove debris and prevent wear.

Bearings play a vital role in ensuring the smooth operation of the equipment. The maintenance cycle for bearings is approximately every 6 - 12 months. Proper lubrication is key to bearing maintenance. Grease lubrication is commonly used, and the amount of grease should be appropriate. Over - greasing or under - greasing can both lead to bearing failure. Regularly check the bearing temperature and vibration to detect potential problems early.

Pump sets are responsible for fluid transportation in the production process. The maintenance cycle for pump sets is every 4 - 8 months. Clean the pump sets regularly to prevent blockages. The lubrication of pump set bearings should be carried out according to the specified intervals. Check the pump performance parameters, such as flow rate and pressure, to ensure normal operation.

The concept of preventive maintenance is to identify and address potential problems before they cause major failures. The implementation steps include establishing a maintenance schedule, training operators, and using advanced monitoring tools. Regular inspections are of utmost importance. By conducting routine inspections, operators can detect early signs of equipment problems and take timely measures to prevent breakdowns.

Identifying common faults in palm oil production equipment is essential for quick problem - solving. For example, abnormal noise may indicate gear wear or bearing damage. Pressure fluctuations in the system can be a sign of pump problems or blockages in the pipeline. By analyzing these symptoms, operators can quickly determine the source of the problem. Here is a simple table showing some common faults and their possible causes:

| Fault Symptom | Possible Cause |

|---|---|

| Abnormal noise | Gear wear, bearing damage |

| Pressure fluctuations | Pump problems, pipeline blockages |

In case of equipment failures, having an emergency handling procedure is crucial. First, stop the equipment immediately to prevent further damage. Then, use diagnostic tools to quickly locate the problem. Once the problem is identified, take appropriate repair measures. For example, if a bearing fails, replace it with a new one as soon as possible. The goal is to minimize downtime and resume production as quickly as possible.

In addition to the maintenance of core components, auxiliary maintenance is also essential. Water quality management is important because poor water quality can cause corrosion and scaling in the equipment. Replace seals regularly to prevent leaks. Conduct electrical safety inspections to ensure the safe operation of the equipment.

In the industry, many companies have accumulated valuable best practices. For example, some companies use predictive maintenance technology, which uses sensors and data analytics to predict equipment failures in advance. On - site tips include keeping the equipment clean, storing spare parts properly, and training operators regularly. As a well - known industry expert said, "Proper maintenance is not only about fixing problems but also about preventing them."

The Penguin Palm Oil Pressing Production Line comes with global technical support and a 2 - year warranty on core components, ensuring long - term stable operation of your equipment. Click here to get a customized maintenance plan now!