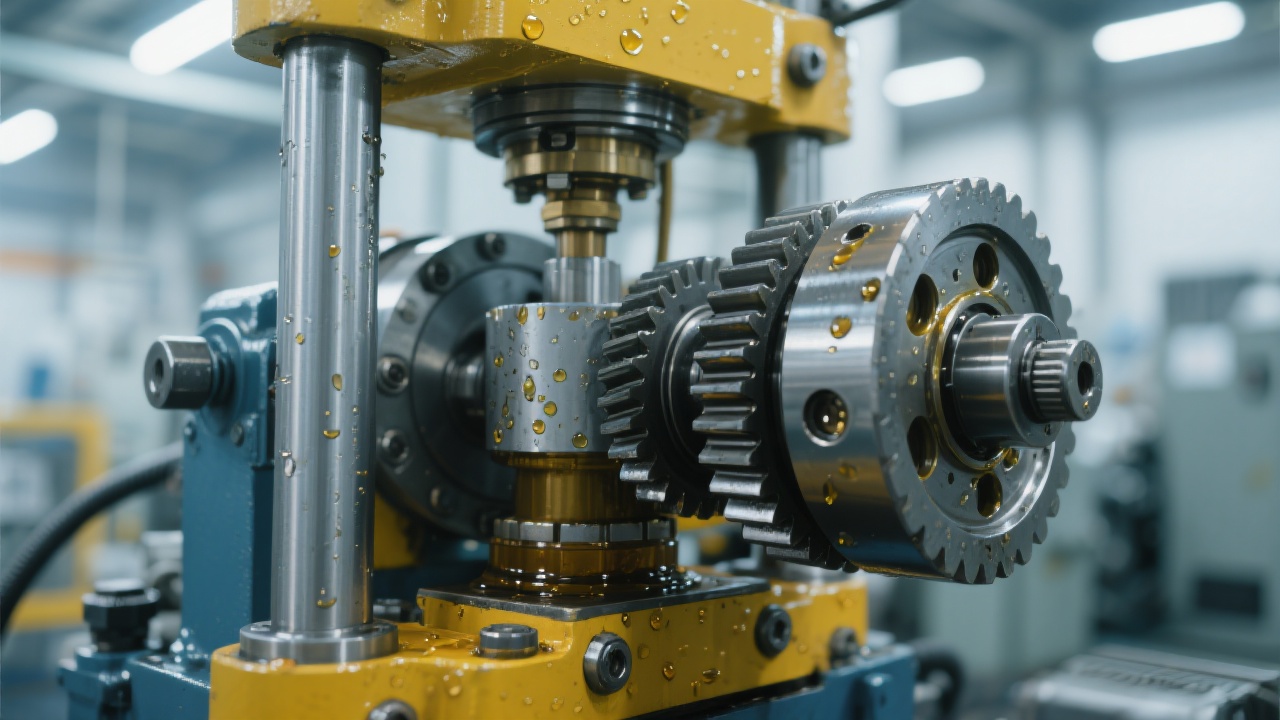

Operating a palm oil pressing production line requires attention to detail, especially when it comes to minimizing unexpected downtime. You understand that any halt in production doesn't just cost time—it severely impacts your bottom line. This guide equips you with actionable preventive maintenance strategies focused on key equipment parts like gears, bearings, and pump assemblies, enabling you to safeguard your investment and enhance operational efficiency.

Preventive maintenance (PM) is a proactive approach that involves routine inspections and servicing to prevent equipment failures before they happen. In your palm oil production line, applying PM means scheduled lubrication, condition monitoring, and timely part replacements. Maintaining a strict schedule reduces unplanned downtime by up to 40%, according to industry benchmarks.

Key steps include:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Gears | Visual wear check, lubrication | Monthly |

| Bearings | Noise/temperature monitoring, lubrication | Biweekly |

| Pump Assemblies | Seal inspection, pressure setting calibration | Monthly |

You should pay close attention to early warning signs such as unusual noises, vibrations, or pressure inconsistencies in your equipment. For example:

When you detect any fault, it's critical to initiate a structured emergency protocol to minimize impact:

Your maintenance strategy isn't complete without addressing auxiliary systems. Manage water quality by ensuring Total Dissolved Solids (TDS) remain below 500 ppm to prevent corrosion. Replace seals proactively every six months to avoid oil leakage, which compromises both safety and yield. Additionally, conduct quarterly electrical safety checks adhering to IEC standards, preventing costly failures and safety hazards.

| Maintenance Aspect | Key Parameter | Recommended Frequency |

|---|---|---|

| Water Quality | TDS < 500 ppm | Monthly |

| Seal Replacement | Wear resistance check | Every 6 months |

| Electrical Safety | Compliance with IEC standards | Quarterly |

Adopting these comprehensive maintenance practices leads to significant improvements. For instance, consistent steam consumption per ton of oil can be optimized to <= 300 kg, directly lowering energy costs while boosting output.

Remember, your palm oil production efficiency hinges on a systemized equipment health program integrating these practical insights and industry best practices.

Leverage on-site experience by encouraging your operators to keep daily logs of operational irregularities. Implement periodic cross-team reviews of maintenance data to refine schedules dynamically. Finally, invest in quality lubricants and certified spare parts to extend asset longevity.

Approach preventive maintenance not as a cost but as a critical investment for consistent productivity and profitability. Your equipment deserves nothing less than a meticulous, data-backed maintenance program that anticipates issues before they escalate.